Our 3D printed Terminator arm: able to withstand any metal crusher (Cyberdyne microchip not included).

By Emily Lehmann

Arnie is back. Yes, you better believe it: the Terminator is out once again in full 3D glory… but he’s not just on the big screen.

After watching the fifth instalment Terminator Genesys over the weekend, we got to thinking: could we build our own Terminator cyborg, only better? The answer is, of course we can – we’re CSIRO!

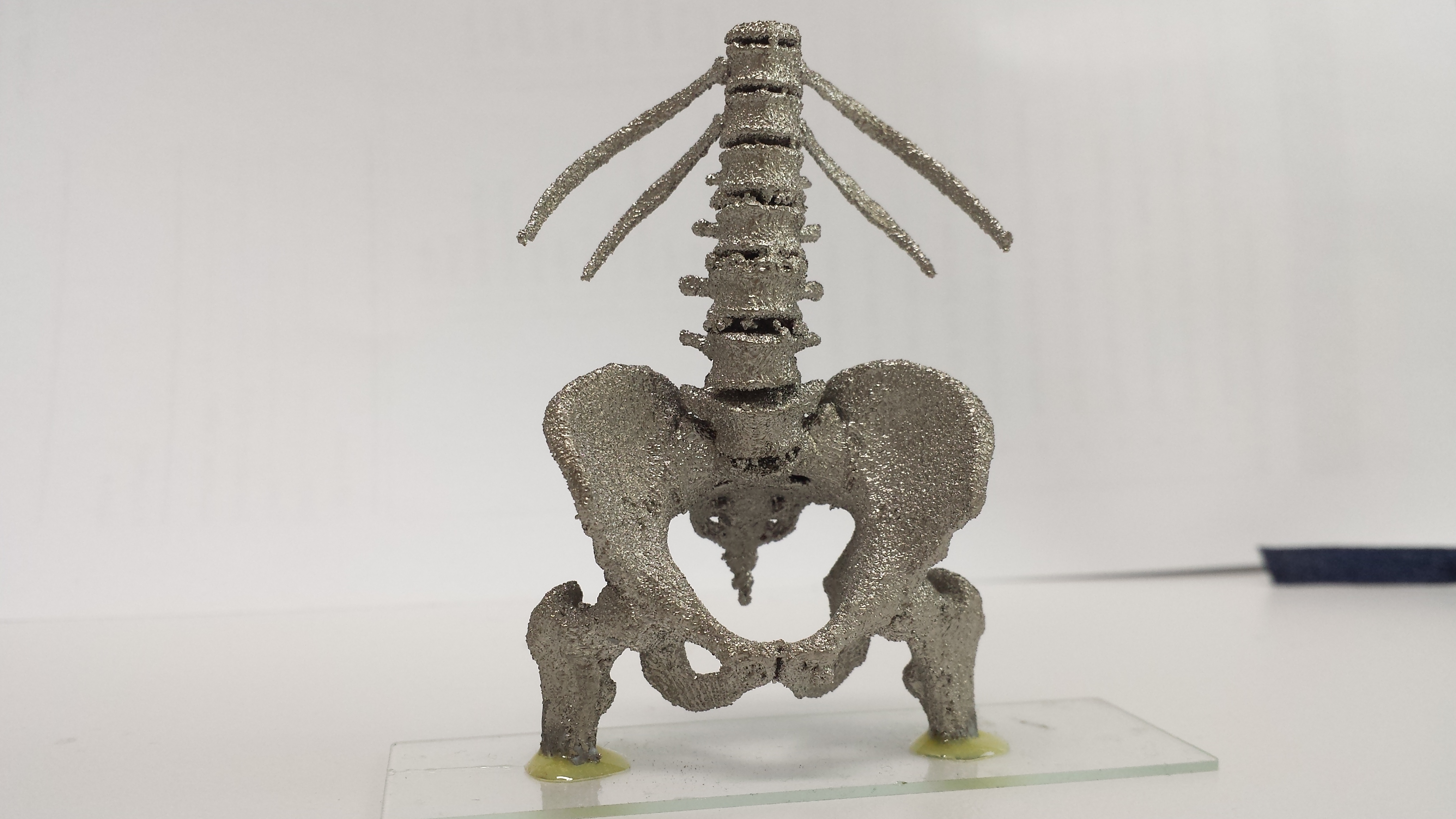

Down at our underground resistance base Lab 22 we’ve started working on a 3D metallic Terminator-inspired skeleton. The new model, dubbed the Ti-1000, is made of super strong and lightweight titanium, so it can take down mortal Cyberdine enemies with greater speed and agility.

Our key advantage is that our Ti-1000 models are 100 per cent customisable on demand, so there won’t be any Skynet showdown they can’t handle.

We can respond to specific (state of) emergency market needs by 3D printing tailor-designed precision parts with the right qualities for the job. In fact, our sinister looking Terminator hand and pelvis were delivered with rapid response from concept to creation, in under a week!*

The pelvis was easy, but the living tissue over endoskeleton is a work in progress.

We also have top-notch facilities at our doorstep meaning that we can continue to tweak and enhance our Terminator assemblage.

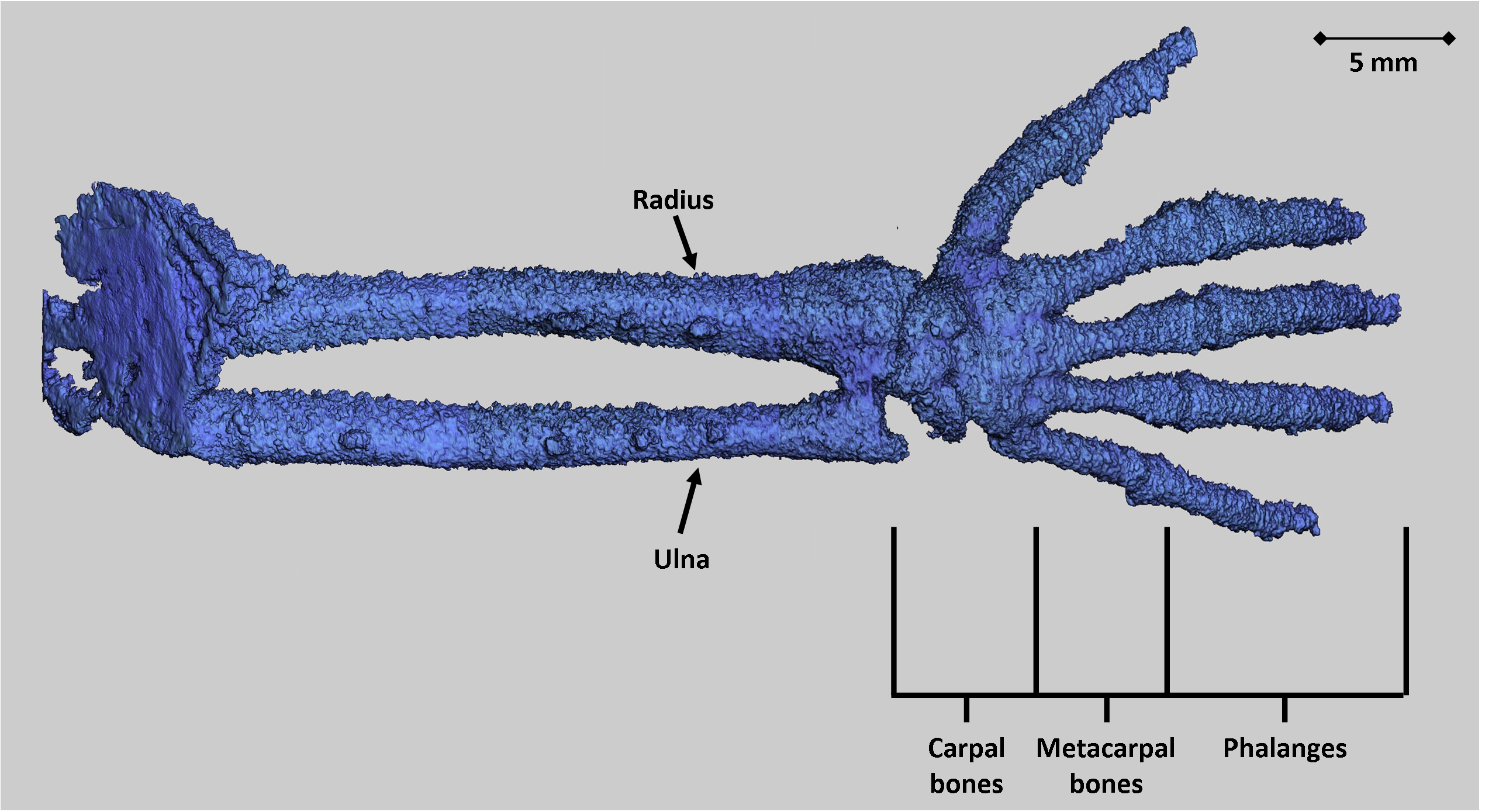

We recently took our parts, among other (more serious) top secret industrial designs, to the Australian Synchrotron where we used the imaging and medical beamline to create precisely detailed 3D images.

Zooming in on these pieces can tell us a lot about our products and the processes we’re using to create them. For example, it can help to expose any faults in the end-product so that the manufacturing process can be improved. After all, consistency is about ensuring that every Ti-1000 model has the same chiselled Schwarzenegger features.

Improving the process will lead to better performing, higher quality and more consistent results for Cyberdyne Systems manufacturers every time.

If ever there’s a Terminator 6, then we’ve got the next generation model covered. But until then:

P.S. While some of this blog may be science fiction, there are real bona-fide stories coming out of our Lab 22 and 3D printing facilities, such as a world-first 3D heel implant and a horse-orthotic. You can find out more, including how to do business with us, here.

*Unfortunately, we can’t send them back in time… yet

17th March 2017 at 12:38 am

Very impressive! Who does not want to have something like that from titanium parts at home?

7th July 2015 at 12:40 pm

Brilliant – can you also make it liquefy then re-gloop* after pouring itself through a hole in the elevator? Wrong terminator I know, but Arnie could do with an upgrade.

*re-gloop isn’t a bad word for it, is it? I might claim it as my own if it goes viral (or has it already. I’d better check)