By Sherrie Wilson

Could rocks hold the key to a healthier planet? Image: Pacific Northwest National Laboratory.

Our scientists in Western Australia are busy developing technology that could significantly reduce emissions of greenhouse gases. One of the exciting technologies being explored is carbon capture and storage (CCS).

CCS involves capturing carbon dioxide (CO2) that would otherwise be released into the atmosphere, compressing it, piping it to a suitable site, and injecting it into deep geological formations where it can be stored safely for millions of years.

They are currently looking at core samples taken from the south west of Western Australia, to determine whether the rock below can be used for the secure storage of CO2. The rock needs three features to be suitable:

- Sufficient pore spaces in which CO2 can be contained (porosity)

- Pathways connecting the pore spaces for the CO2 to move through (permeability)

- A solid, sealing layer of rock on top of the porous, permeable layer, to stop the CO2 moving outside the target area (seal).

Scientists have offered a delicious example of why these geological features are important.

Choca-block

Let’s consider a Tim Tam and an Aero bar as two possible types of reservoir rock and milk as our CO2. Both chocolate bars have plenty of porous space in them, yet if you bite an end off each and try to use them as a straw to draw milk through, the permeability of the Tim Tam will allow the milk to be pulled through the porous spaces into your mouth, but the Aero bar won’t.

The Aero bar, although seriously delicious, has no chance of holding your milk. Image: Trypophobia.com

This is because the Aero bar, although porous, does not have any channels connecting the spaces and therefore the milk cannot move through the chocolate. The principle is the same for the reservoir rock needed to store CO2. The CO2 needs to be able to move through the rock and fill all the porous spaces.

Hard-core pore

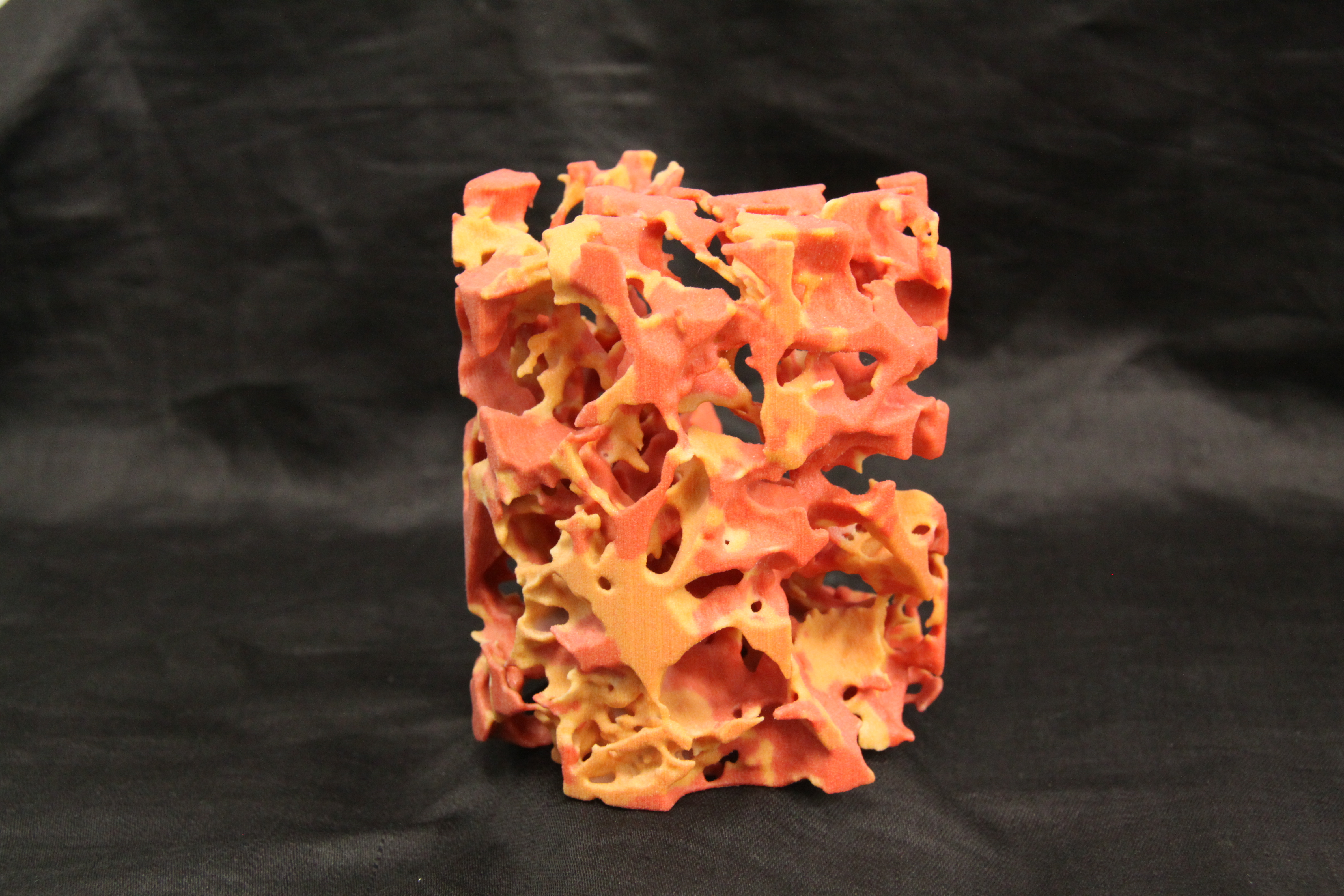

To help visualise the spaces inside the rock where CO2 (or oil, natural gas or formation waters) will move through and be stored, we’ve teamed up with Lithicon Australia to bring the core samples to life. Lithicon Australia use a type of CT scanner and leading-edge analysis to produce 3D photographs of the core samples. From those images they are able to print physical 3D models.

These models represent a seriously tiny piece of the original core sample (0.8 of a millimetre in diameter). They also help us recognise that the spaces where CO2 (and oil and gas) sit within rock are not the big caverns that we often envisage, but a series of very small interconnected spaces.

With ongoing advancement and increasing accessibility of printing technology, it’s likely that 3D models like these will be utilised more often in future projects, which will provide us with exciting new ways to visualise and analyse geological formations.

As you can see from the core samples (which are equivalent to the rocks from Western Australia) the rock is likely to be sufficiently porous and permeable. Scientists are excited by these initial results, but suggest the core samples are just the first step in a long line of processes that must be undertaken for CCS to begin.

But our use of 3D printing is not limited to the geological sector. The Lab 22 3D printing facility was established in October 2012 and is already being used to manufacture a range of prototype products including biomedical implants, chemical processing and aerospace parts.

Recently we have also used 3D printing to build a new generation of hi-tech fish tags made of titanium, with the aim of tracking big fish such as marlin, tuna, swordfish, trevally and sharks for longer periods.

30th March 2014 at 12:01 pm

Hello,

Thank you for sharing the experience. I am a petroleum engineering student in California. I was wondering if you can provide me with more information about the reservoir rock sample 3D printing process such as image resolution, printing scale and the cost as well?

Thank you

2nd April 2014 at 2:44 pm

Hi Cyrus,

The best thing to do is contact the supplier, Lithicon. You can head to their website at http://www.lithicon.com/ or send an email to contact@lithicon.com.

Good luck!

Cheers,

Steph

1st May 2013 at 5:02 pm

Amazing technology! Could you please let me know who to contact for further information on the 3D pore-mapping?

2nd May 2013 at 12:00 pm

Hi Ramona,

The 3D printing of the core sample was done for us by a group over in Canberra known as Lithicon (http://www.lithicon.com/company/), but CSIRO also has some capability in this space.

For instance, our Future Manufacturing team has a 3D printer in Clayton that prints with titanium powder. You can find more info here: http://www.csiro.au/en/Portals/Media/Scientists-use-3D-printing-to-track-big-fish.aspx.