Bottoms up! We’re helping to brew the perfect ale with our Cybertongue® technology.

By Angela Beggs

Last weekend saw the kick off of Good Beer Week. In celebration of this wonderful week, we thought we’d take the hop-portunity to talk about some science that could make it easier for brewers of the future to keep making the best tasting beer.

As all beer fanatics would know, most beer is made from four key ingredients. Barley, water, hops and yeast.

For a brew of the perfect pale ale, you need to extract the sugars from grains (usually barley) so that the yeast can turn it into alcohol and carbon dioxide, creating beer.

Simple, right? Wrong. There are many components of beer that affect the smell, taste and the way it feels when it hits your taste buds.

Our experts in microfludics have used a biosensor to measure the levels of maltose in beer with a high-tech “lab-on-a chip” we call the Cybertongue® technology.

Maltose or malt sugar, is a stepping stone in the process that converts the starch in barley into the alcohol and fizz in beer. Not much maltose is left at the end of the brewing process, but what there is contributes to the drink’s taste and body. Testing the levels of maltose in beer is something brewers do because too much of it can change the way the beer tastes.

How does it work? Well, our scientists have hijacked the inbuilt sensors that simple microbes use to find their food and re-purposed them to test for the presence of flavour molecules present in a wide range of food and beverages (including delicious beer).

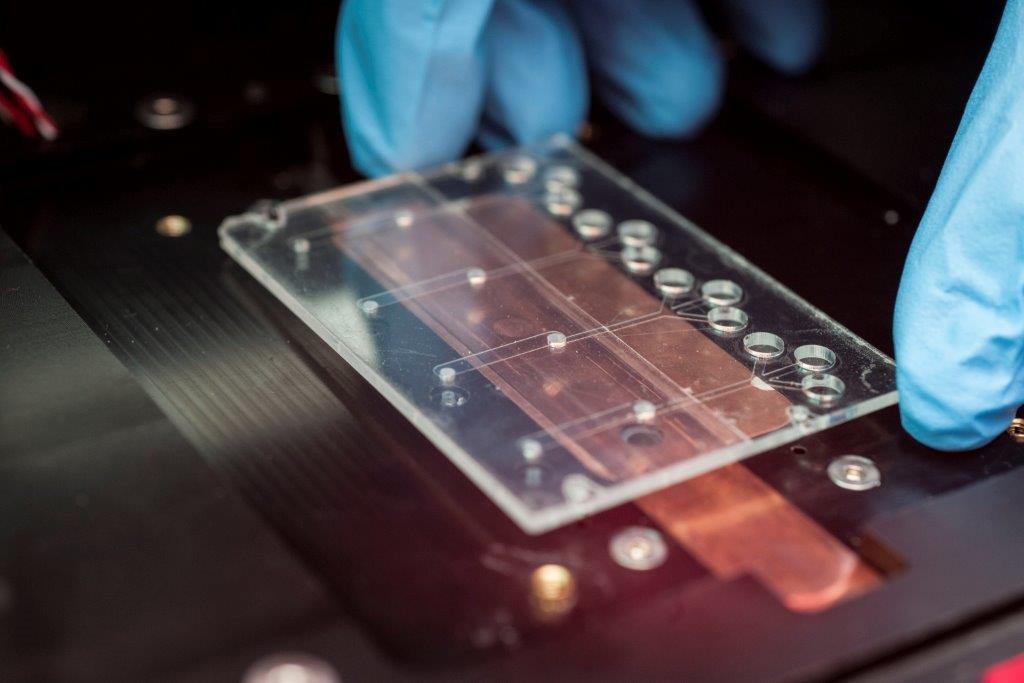

To run the new test all it takes is a drop of liquid amber. In the lab, researchers mix the maltose biosensors with the ale within the tiny channels, of a special lab-on-a-chip – a transparent slice of plastic about the size of a credit card.

Chips and beer anyone? Our lab-on-a-chip measures the levels of maltose in beer in a matter of minutes.

Once the sample has mixed, the measuring begins. Within a couple of minutes, the results are in! Measuring the level of maltose has been possible for many years, but doing it on a chip makes it much quicker and easier than it has ever been before.

This type of technology could be used to ensure quality and consistency across different batches of beer. And, as well as beer, maltose is found in other beverages, cereal, pasta, and in many processed products which have been sweetened, so there may be applications in those areas too.

The same biosensing technology can be used across many different types of beverages and foods, to measure nutritional properties and flavours, as well as guard against toxins or contaminants. In the future it might also be used to warn people with intolerances and food allergies to things like lactose, which is chemically similar to maltose.

***

Dr. Nam Le will be speaking on the Cybertongue® technology, not so much the beer, during May 27-30 at Biosensors 2014.

24th October 2020 at 1:32 am

I never knew that extracting sugar can make beer color change. I have never seen a black color beer ever before in my entire life. Your blog is amazing with new and exciting news. I loved the writing and the concept. This is really amazing, your blog is so fun to read that I actually do not have any clue where my time is gone.

6th July 2020 at 7:23 pm

I really like your writing style, great info, and you putting so much effort into this blog. Thanks for sharing with us.

13th April 2020 at 2:54 am

Professional image editing. photo retouching remove background etc services.

23rd May 2014 at 7:43 pm

Reblogged this on Professional Photo Retouching and Restoration Services.