Google Glass has got nothing on our wearable tech.

Wearable tech is everywhere. Take a glance at your colleague’s arm, you may see them sporting a new smart watch. The person sitting next to you on the train might be wearing shoes that count their steps. This technology has captured the imagination and interest of shoppers and inventors alike. And we’re not immune to the trend.

So it should come as no surprise that our scientists have a few wearable projects up their sleeve.

You may recall the electiFIED backpack Mashable featured earlier this year, or perhaps you read about our wireless ad-hoc positioning system (WASP) for tracking athletes? Well, we’re not done yet, because another of our favourite wearable projects is about to go global.

An Aussie aerospace company, TAE, has just signed an agreement to commercialise our Guardian Mentor Remote platform (GMR).

Think of GMR as a combination of Google Glass, Tom Cruise’s gloves from Minority Report and the ComBadge from Star Trek. GMR is an augmented reality technology that uses a wearable computer, helmet-mounted camera and a near-eye display to remotely connect technicians with aviation experts from around the world.

How will it help the aerospace industry? By connecting experts with technicians remotely, companies can undertake aircraft and engine repairs and maintenance without having to fly in specialist engineers or mechanics.

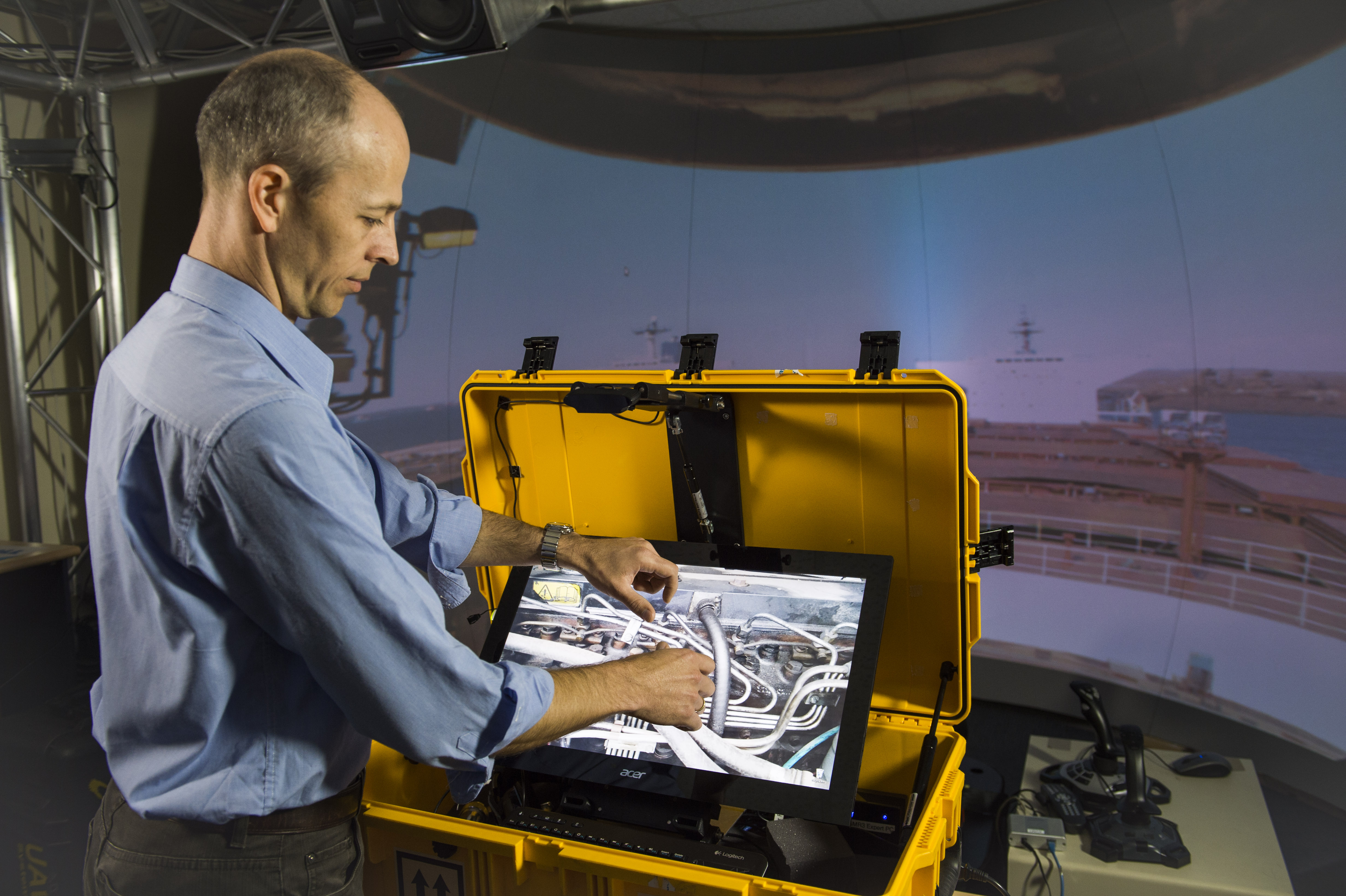

Using this touch screen, experts can see what the technician can see, offer advice and share documents.

It’s not enough to connect a technician and an expert via a video conference. The GMR system allows an expert to see exactly what the technician is seeing, make suggestions, share technical documents and annotate the information in real-time.

For technicians it will be like having an expert in the room with them, even if they’re in another state or even another country. That means there’s no more waiting days to get aircraft back up and running.

Maintenance is a big issue for the aerospace industry. If a plane’s not operational, it can cost a company up to $12,000 per hour and worse cause massive delays. This is why the likes of Boeing and Aviation Australia have already trialled the GMR prototype. And now that TAE is commercialising this technology globally, our device is set to reduce aircraft down-time and maintenance costs for commercial, regional and defence aircraft operators worldwide.

The GMR is not just limited to the aerospace industry, already we are seeing interest from other sectors including the manufacturing, mining, automotive, paper and pulp and rail industries. It could even be used to provide remote medical assistance for field health workers and emergency scenarios.

17th August 2015 at 6:35 pm

very nice and informative post