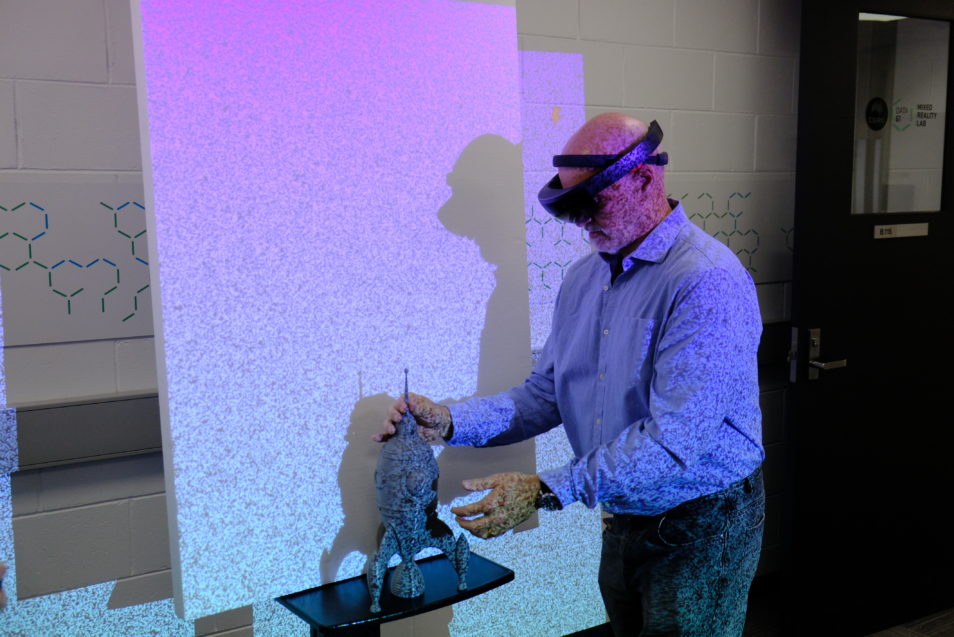

An object being scanned using our patented technology to estimate its depth.

Imagine the future of smart factories where you could digitise the entire process of designing, producing and distributing items? You could see the process on a screen before it happens, leading to better decision making and planning. Well, this new production method is at the core of our new Mixed Reality Lab.

The newly-launched Melbourne lab enables organisations to create ‘digital twins’, or computer-generated copies of real-world objects. This will be a technology game-changer for manufacturing and other industries.

The lab houses a set-up of cameras and sensors that capture detailed information about a physical object and the space surrounding it. Then sophisticated algorithms merge enormous amounts of collected data to create the object’s digital twin. All in a matter of minutes.

Digital twin for the win

Digital twins could improve product innovation and productivity by 25 per cent by 2020, according to the International Data Corporation. Our Mixed Reality Lab will give Australian manufacturers that competitive edge.

For example, a company could use a digital twin to test for weak spots that will be damaged in transit or over the life of the product. This is a quick, accurate and cost-effective way to identify defects before they even happen.

“Defective components can be identified in real-time and corrected. While downstream processes can be adjusted to minimise the impact of delays,” senior software engineer with our Data61 team Matt Bolger said.

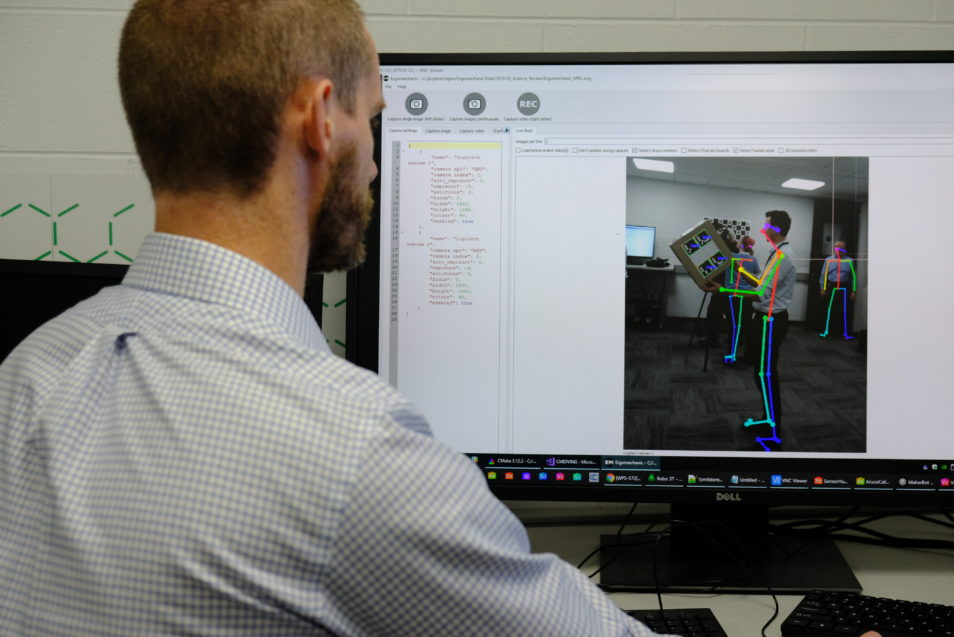

The lab’s technology can also be applied to humans to analyse their movement using deep learning and biomechanical modelling.

Snap back to reality

The Mixed Reality Lab can be scaled to the size of the object being scanned. So, it can be tailored to create products for health, agriculture and mining, as well as manufacturing.

“Our technology can also be applied to humans to analyse their movement, using deep learning and biomechanical modelling,” Matt said.

“This could help elite athletes improve their performance and reduce workplace injuries.”

Dr Simon Barry, analytics and decision sciences research director in our Data61 team said the Mixed Reality Lab is an example of the Fourth Industrial Revolution in action. This is where technology plays a more apparent role in our lives as lines are blurred between the physical, digital and biological spheres.

“This is the future of smart factories. The digitisation of the full value chain will enable real-time situational awareness and lead to better decision making and planning,” Simon said.

“Digital twins of manufacturing processes, human movement and even our cities and infrastructure will significantly improve productivity, reduce costs and transform all manner of industries,” he said.

So how does it work?

To request a transcript please contact us.

An example of how the technology could be applied in a manufacturing scenario.

- Manufacture an object

- Scan the physical object using the Mixed Reality Lab

- The data is collected and analysed with our algorithms

- The digital twin is compared to the manufactured object to identify defects or variations

- Using augmented reality, the digital twin can be displayed over the manufactured object to identify defects.

15th February 2022 at 11:15 pm

Great read! Digital twins can be used in various scenarios. For example, you can organize virtual machine training sessions before allowing your new hires to use the actual machines.