HMAS Rankin, sixth submarine of the Collins class, underway in 2006 Image: James R. Evans

HMAS Rankin, sixth submarine of the Collins class, underway in 2006 Image: James R. Evans

It probably doesn’t bear thinking about if you’re claustrophobic, but the only thing in shorter supply on a submarine than space is oxygen. From the moment a sub closes its hatches and dives it’s a sealed container full of people. Everyone’s breathing that oxygen in and breathing out carbon dioxide. Devices called oxygen generators help by creating oxygen from the electrolysis of water, but eventually all non-nuclear submarines have to surface to replenish oxygen supplies for the crew and the sub’s engines.

That process, where oxygen is drawn in and contaminants such as carbon dioxide are expelled, is known as “snorting”.

Submarines are never more vulnerable than when they’re on the surface and exposed, so navies around the world are focused on improving the underwater endurance of their subs, and decreasing the amount of time they spend “snorting”.

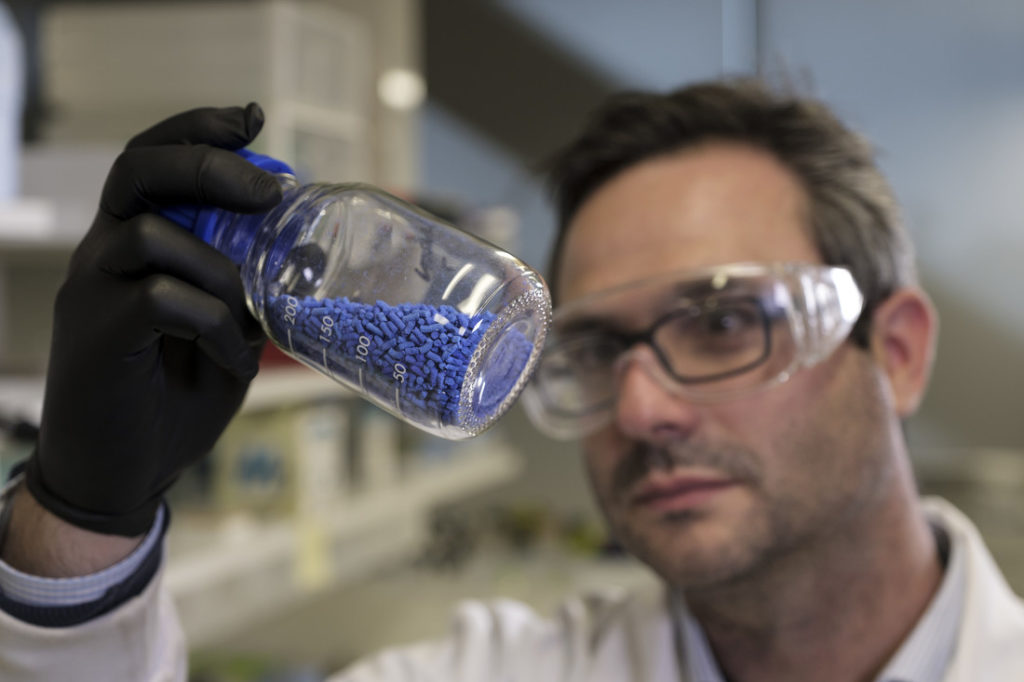

These blue pellets are MOFs and could be coming to a submarine near you.

These blue pellets are MOFs and could be coming to a submarine near you.

Under the Sea

That’s where we come in. Along with our partner, technical and engineering services company QinetiQ, we’re testing a new way of removing carbon dioxide from a sub’s atmosphere while submerged. By stopping carbon dioxide from building up to dangerous levels a sub can remain stealthy and submerged for longer.

The equipment used to do this is called a carbon dioxide scrubber. The problem with current versions is that they take up a lot of finite space and weight on a sub, while sucking up plenty of energy as well. Worse still, they release corrosive gases which can eventually damage the sub’s systems.

It’s better

With QinetiQ, we want to come up with a better way to remove carbon dioxide from a sub’s atmosphere, and at the centre of it are MOFs. Metal Organic Frameworks (MOFs) have the largest internal surface of any known substance, are extremely porous, and can be enhanced to capture specific gases, such as carbon dioxide. We already have a lot of experience and expertise in using MOFs with carbon dioxide.

We’re now testing MOFs to find one perfect for operating in a sub. We think MOFs could allow a sub to stay underwater longer by removing even more carbon dioxide and improving the quality of the atmosphere. It could also take up far less room and place a lot less strain on the sub’s critical energy systems. All this while providing a simpler system that requires less maintenance.

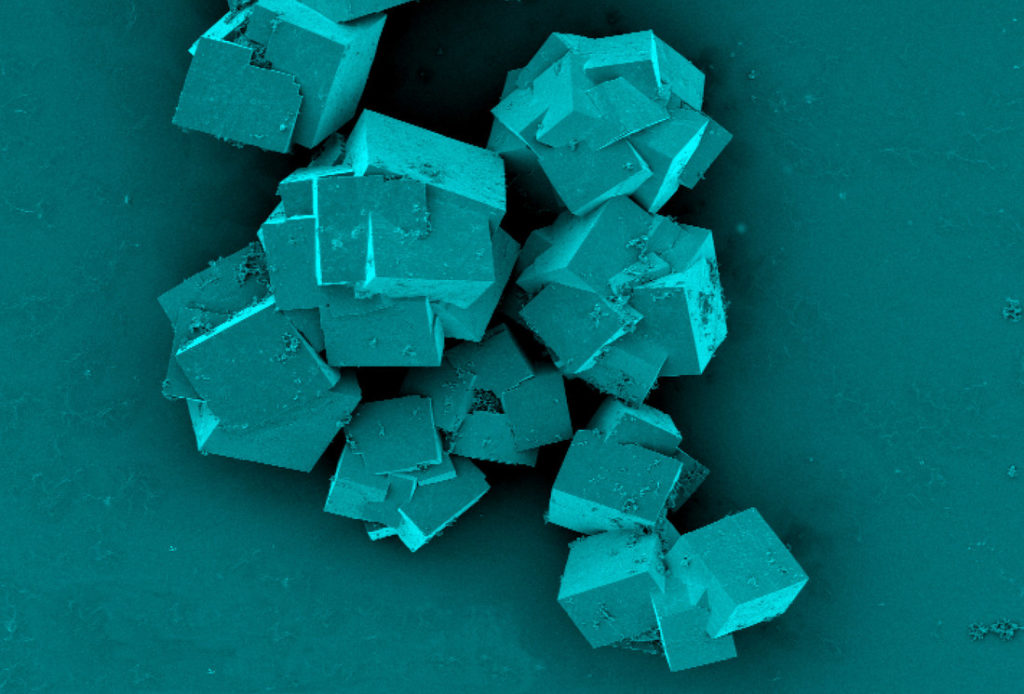

What MOFs look like under a microscope

What MOFs look like under a microscope

Down where it’s wetter

If successful, we’re aiming to get world first MOFs based carbon dioxide scrubbers onto the existing Collins class submarines, to extend their operational life and capabilities, as well as on Australia’s next generation subs. The Future Submarines Program (SEA1000) is the largest and most complex military program ever undertaken in Australia and will see 12 cutting edge submarines built in Australia.

10th April 2018 at 7:58 am

the issue is portability

ie. probably not

10th April 2018 at 7:56 am

In some future war, submarines will be one of the few survivors after a period of a few weeks. Whils there is a focus on enhancements to underwater endurance, little is said about the battery. Collins boats have quite conventional lead acid cells by Varta, but if we went to even old now inapplicable ni-cad battery, which release energy at 2.4x the power, and while the dash speed of Collins boats is secret, healthy improvements can be seen. The market run in this class is 30 knots submerged. On the basis of twice as fast require 8x the energy, a re-equipped Collins could make 40+ knots, exceeding the speed of the surface vessels that could pursue it.

Then there is the noise signature. All submarines have a noise signature which enemy and friendly software will analyse to determine what the received noise comes from. There is a principle called anti-noise, so easy car manufacturers use it. Manipulating the sine signature noise could either make the boat invisible, or she could be who ever you want her to be, given the signature could be manipulated to any other class of boat

9th April 2018 at 11:45 pm

Hmm interesting but guessing requires air already to work then purifies the air taking out CO2. On boats were also used a CO2 canisters but were like cork like looking…

On diving equipment maybe via the tank to the mouth piece in between so less oxygen is expended by diver or CO2 lessened when expelled just a thought..!

9th April 2018 at 9:28 am

How extendable is this research for use in underwater diver’s rebreather apparatus?

11th April 2018 at 9:06 am

Hi James,

This research could potentially be used in underwater diver’s rebreather apparatus.

Cheers,

Ellen

CSIRO Social Media

Pingback: How we’re helping the navy with its snorting problem | Richard Howell Blog