CBG Systems has been a manufacturer of passive fire protection systems for the past 30 years and their panelling is currently found on 90 per cent of the world’s high-speed ferries. Photo by CBG Systems.

Whether you’re in a home, apartment or sailing the high seas, you want to know your walls are fire resistant. Despite spending their lives in the water, ships and boats can catch fire causing damage to the vessel, passengers and crew onboard. Luckily, our scientists have come up with a way to keep you fire-safe on land, and at sea.

This will resin-ate with you

We recently worked with CBG Systems, a Tasmanian-based manufacturer of fire-resistant panels for catamarans and ferries. They wanted to find a solution to insulate steel-hulled ships.

Back in the lab, our materials scientists were creating a ductile adhesive resin. This resin or coating is able to weather the toughest conditions and bear considerable load. And importantly for making surfaces fire-resistant, this resin can withstand temperatures over 1000° C. Plus it’s tougher than existing thermal coatings making it perfect for fire-resistant ships.

Weighing about half as much as traditional metal cladding, the resulting reduction in fuel consumption will lower carbon emissions. This will lead to greener ships across the globe as well as enhancing overall operational efficiencies.

Originally, this polymer was to be an adhesive. But our scientists are always wanting to get the most out of our discoveries. So, we got to work with CBG Systems to turn our resin into the vital component in insulation for fire-resistant ships.

You might also be interested in a resin we created to preserve famous artworks.

The innovative panels use a thermal non-intumescent based protective coating that applies our patented Hybrid Inorganic Polymer Systems (HIPS) technology. Photo by CBG Systems.

Creating a new resin for fire-resistant ships

Before we went overboard, there was a little more work to do in the lab. Our resin needed to pass every test and meet the requirements of ship insulation. We worked with CBG Systems’ existing insulation and together we created a composite material to meet fire and weight reduction specifications. From there we began prototyping a new generation of panel for manufacture.

Our lead researcher Mel Dell’Olio worked at CBG Systems for four months. This was to make sure their employees were skilled in advanced manufacturing techniques. It was also to help prepare them to meet the demands of the international market.

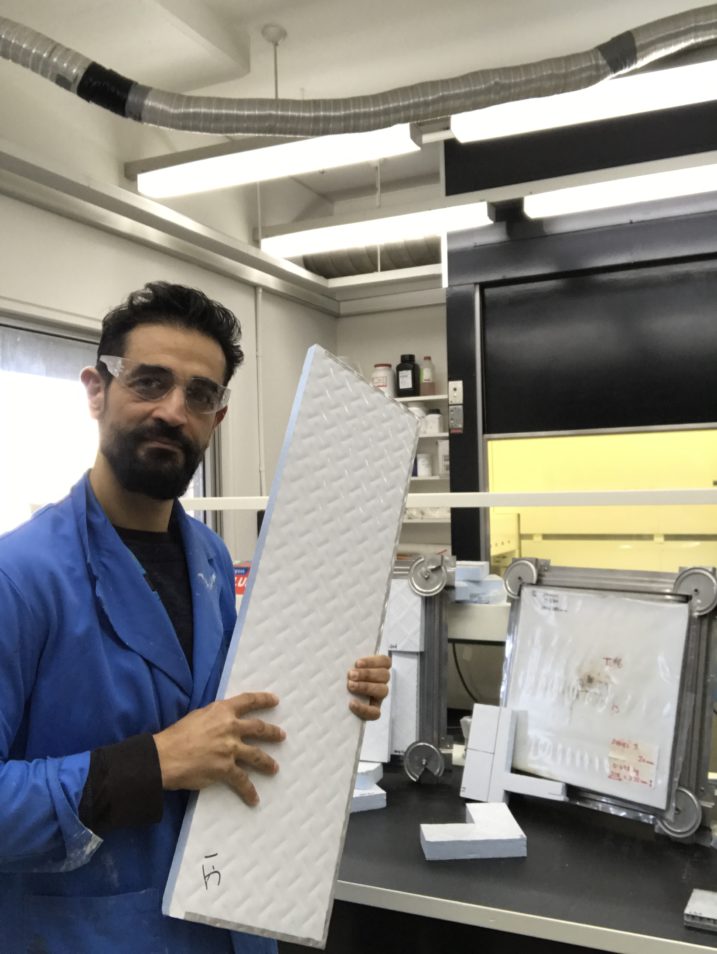

Senior experimental scientist, Mel Dell’Olio, holds up a sample of the new and improved RAC Plus fire-resistant panels.

The new and improved panels, with greater durability and fire-resistance, can be used on steel ships and aluminium high-speed crafts. There are also potential applications in aerospace such as for battery enclosures, and the civil construction industry.

CBG Systems have manufactured passive fire protection systems for 30 years. Their panelling is on 90 per cent of the world’s high-speed ferries. Photo by CBG Systems.

Further support grant-ed

The project received funding under the Australian Government grants program. They were able to build a state-of-the-art manufacturing facility in Hobart, creating manufacturing jobs in the process. As a result, CBG Systems are one of the most competitive manufacturers of marine insulation products for the marine industry. This project has attracted interest from Spain, Denmark and the Caribbean who’ve already placed orders to fit out their new ships.

With three ships already ordered, and two ships complete, CBG systems has hired for six new roles, with partners and suppliers also increasing their staff as a result.

19th June 2020 at 3:14 pm

I wonder if this material would be light enough to be used to protect the firewalls in light aeroplanes against engine fires?

20th June 2020 at 11:33 am

Hi Evan,

The resin has a lower density than Aluminium and Steel. It would depend on how much volume (resin + fibre) you need to pass the related fireproof test to ascertain if the composite is light enough overall. Definitely worth pursuing with further composite optimisation to meet the specific fire ratings.

Thanks,

Georgia

Team CSIRO

17th June 2020 at 5:16 pm

Would these panels be useable as panels (structural) walling caravans? Would there be a weight penalty compared to conventional caravan materials?

20th June 2020 at 11:32 am

Hi Chris,

Thanks for your question. The structural components that make up the composite along with other structural fibres can potentially be reconfigured to form a composite type caravan assembly. The fire-proof resin, which can be used to replace conventional fibreglass resins has equivalent densities, so we do not believe weight increases would be a deterring issue.

Thanks,

Georgia

Team CSIRO

17th June 2020 at 10:32 am

Love your great stories. Would love to see and hear more about the flora of our deert areas especially the Nullabor Plains. I also paint the disappearing herbaceous flora of Western Sydney.