By Angela Beggs

You may recall that last year we announced the work we were undertaking to support PATH’s rotavirus vaccine development project?

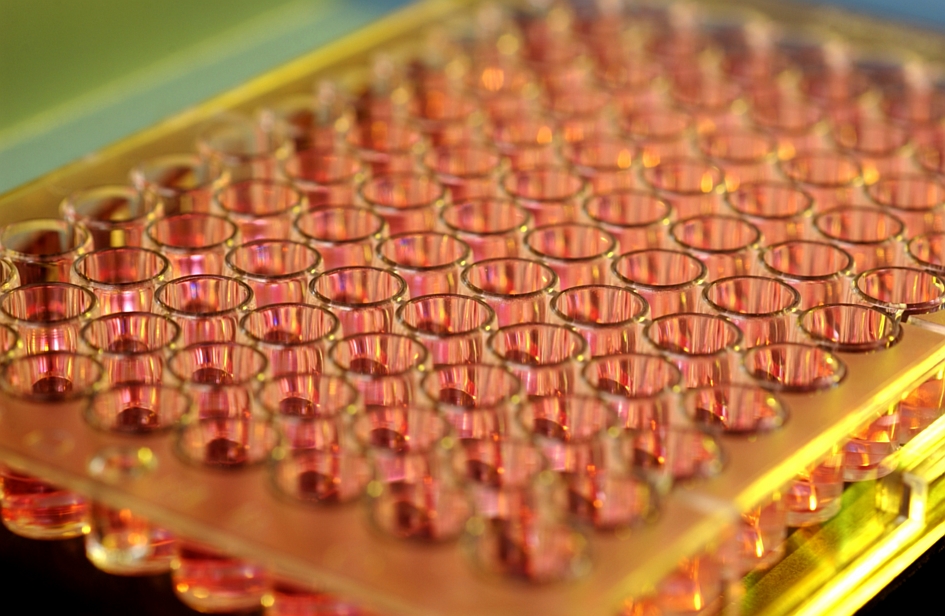

Well, we’ve shipped off 6,000 vials of antibodies which will be used to control the quality of new vaccine candidates under development for rotavirus – which is a major cause of severe and fatal diarrhea, killing half a million children living in developing nations per year and leaving millions more in hospital [1].

Almost every child across the globe is at risk of contracting rotavirus, but access to appropriate treatment for severe diarrhea and dehydration is limited or unavailable in many developing countries, which is where 95 per cent of all rotavirus deaths occur [2].

Although commercial vaccines do currently exist, they are not widely available or affordable in many parts of the world. Additional new vaccines will mean cheaper and more accessible prevention methods for kids in India, China, Brazil, and beyond.

There have been a number of research agencies working with PATH in development of the antibodies that recognise the different strains of rotaviruses.

These antibodies are required in large amounts for use as quality control reagents by vaccine manufacturers.

CSIRO’s state-of-the-art protein production facility at Clayton provided the capabilities and infrastructure to allow us to perform large-scale production of these different monoclonal antibodies and supply these quality reagents.