Catalytic static mixers are a game-changer for chemical manufacturing. We explain why and how they work.

Just about everything we use has chemicals in it. From pharmaceuticals to fragrances, food flavouring and garden supplies.

You may think chemicals are easy to mix together because they’re in so much of what we use daily, right? But that’s not always the case. Some chemicals can be pretty difficult to make. The components may mix inconsistently, there could be problems with heat during manufacturing or pressure inside the batch reactor used to make the chemicals. And many chemical intermediates can be hazardous or even explosive.

So, making chemicals is a tricky business. That’s why the world-leading researchers at our FloWorks lab in Melbourne use flow chemistry to support Australian businesses. Flow chemistry makes chemicals more efficiently than through traditional batch chemistry. As a result, they’ve supercharged chemistry by inventing a suite of special devices called catalytic static mixers or CSMs.

CSMs are the latest development in flow chemistry. The CSMs do the mixing as chemicals are pushed through the small flow chemistry tubes. It’s a new and exciting way of manufacturing everyday chemicals that is cleaner, safer and more cost-effective. They consequently help make chemical manufacturing much easier.

But first, what is a catalyst?

A catalyst is a substance that can be introduced to a chemical reaction to increase the rate of reaction. It does this by lowering the amount of energy needed to get a reaction started. Usually, scientists only require a small amount of catalyst to do this. But here’s the good news. The reaction process doesn’t consume catalysts while it’s happening. So scientists can use them over and over again.

Catalysts are also everywhere. Look around you. They’re responsible for making bread and beverages, perfumes and cleaning products, as well as your car’s petrol. Even nature uses catalysts broadly. For example, our bodies’ enzymes work as catalysts to make our digestive and muscular systems work.

Mixing it up

The combination of smart design, 3D printing and novel catalyst materials make catalytic static mixers highly customisable for specific purposes.

CSMs are a game-changer in chemical manufacturing.

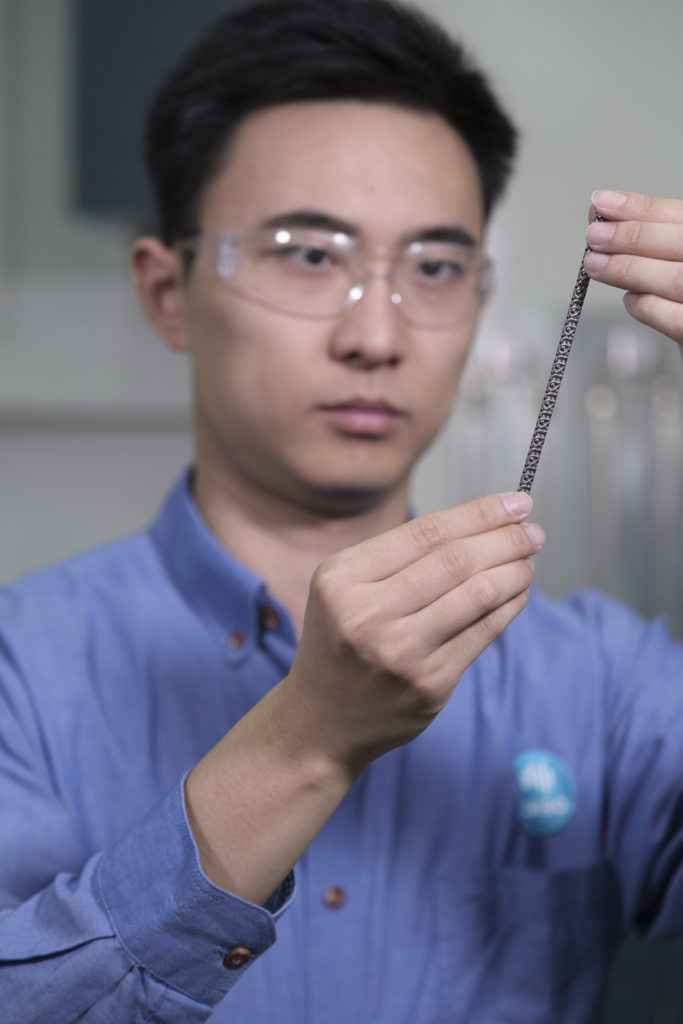

Resembling a bejewelled metal straw, these intricate and carefully designed mixing structures can greatly speed up specific chemical reactions.

Positioned within tubes inside the flow chemistry reactor, chemicals flow through each CSM and mix as programmed. Each design determines how a chemical process will mix, and when and how catalysis will occur.

We make CSMs through 3D metal printing. This manufacturing process gives us a range of design freedoms. In turn, it makes CSMs highly customisable for specific purposes, leading to their intricate designs. Using computers to model how different molecular structures will interact with different CSM designs ensures there’s a perfect mixer for every job.

A wide range of catalyst materials coat CSMs. Especially noble metals like gold, palladium and platinum. These metals are ‘noble’ because they don’t dissolve or oxidise easily, therefore making great catalysts. Fun fact: noble metals are the same catalyst metals that car exhaust systems use to get rid of toxic pollutants.

The combination of smart design, 3D printing and novel catalyst materials result in a better way of making chemicals.

We’ve got catalytic static mixers in our future

Local coating specialists, Precision Plating, coated the CSMs for us. They were so impressed by our CSM technology, they decided to license it! They’ve even spun out a company called Precision Catalysts to coat and sell CSMs for local and international markets.

Precision Catalysts will provide CSMs to Merck, a leading global chemical distributor. The flow chemistry lab at the University of Graz in Austria is an early adopter and has already seen what our CSMs can do.

You may never get to see our CSMs yourself. But as more chemical manufacturers adopt flow chemistry technology, this homegrown Aussie innovation will someday help make the designer fragrances you wear, the food flavouring you eat, the fertiliser in your garden, and the pharmaceuticals in your bathroom.

We’ve published scientific papers in different fields using CSM technology. We’ve also filed six international patents covering the design and additive manufacturing process of the static mixers, application of the catalytic coating, and the incorporation of the CSM into a continuous flow chemical reactor chamber. Here’s an explanation of what they are.

We’re also supporting work led by the Department of Industry, Science, Energy and Resources (DISER) to implement the Modern Manufacturing strategy. This whole-of-government strategy aims to help Australian manufacturing scale-up and become more competitive and resilient, creating jobs now and for future generations.

31st March 2021 at 9:09 am

Hi, is there a way to contact you for mor information on a specific request?

14th January 2021 at 11:47 pm

The mixer design isn’t new I’ve seen it in a 15 year old machine except was larger and made from 1mm sheet steel, interlocked at 45, welded, then turned to diameter.

19th January 2021 at 8:55 am

Yes static mixers have been around for quite a while. Catalytic static mixers have not.

14th January 2021 at 6:17 pm

Very impressive…innovation and development is extremely important in ramping up our economy.

Congratulations and well donr

14th January 2021 at 1:03 pm

Slick concept. 3D printers continue to provide unexpected gains in an ever widening range of applications.