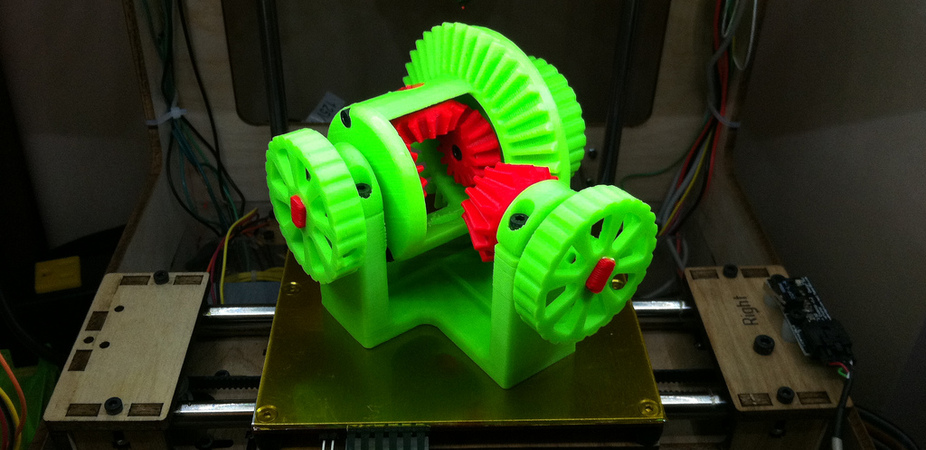

3D printing holds many advantages for the manufacturing industry, including the ability to print moving parts. Image: John Biehler.

By John Barnes, Titanium Technologies Leader

It’s not easy being a small business in the current manufacturing environment. The face of manufacturing is changing, and businesses are eager for technological advances that could give them a competitive advantage.

Maybe 3D printing can help.

When people think 3D prints, they might think cool-looking guitars, high fashion, dolls that look like you, and even weapons.

But that’s not all 3D printing can do. From design to finished product, 3D printing can speed up and reduce costs in the manufacturing process. Let’s have a look.

The big advantage

Being an additive technology, 3D printing offers significant cost savings by using lower amounts of material than traditional manufacturing methods. When you are forced to cut away from a solid block, removing more material to achieve details increases cost.

Most machines that print in metal can also recycle unused powder (the “ink” of 3D printing).

There are many types of 3D printing technologies available today. They use varying technologies and energy sources to fuse a range of plastic and metal feedstocks, with the plastic printers having the broadest capability.

Plastic printers range from “personal” units sold for thousands of dollars, to complex manufacturing units costing in the hundreds of thousands.

While 3D printing technologies for metals are more uncommon at present, applications for both materials are expanding rapidly.

Design: The time a product spends in the design cycle can affect time to market significantly. Use of 3D printing has been estimated to reduce development time by up to 96%.

After 3D printing, surplus metal powder is recovered for re-use in further manufacturing runs.

Using 3D printing, multiple iterations of product design variations can be explored simultaneously during the conceptual stage of design, without investing in the tools to make the product.

Car manufacturers have used 3D printed mock-ups of parts for years, from rear view mirrors to front end fascias.

The design files for 3D printing can also be sent digitally to a global network of manufacturers in a process known as “3D-faxing”. It has potential to significantly reduceshipping time and costs.

Products can be created at a digital facility as they are needed, eliminating customs inspections and duties and minimising transportation costs.

Tools: 3D printing has been used very successfully to manufacture jigs, fixtures, gauges and shop tools quickly and inexpensively. These are the tools made to assemble more complex parts, and they can be expensive for manufacturers.

3D printer manufacturer Stratasys cites saving up to 90% on fabrication of fixtures, and one-year profit gain of from US$60,000 to 230,000.

A specialised example of this use of 3D printing is use in medicine by surgeons to create mock-ups of complicated surgeries, allowing them to practice before undertaking the surgery – for example, placement of drilled holes to install pins or screws with extreme precision.

Building in one: Many products need to be assembled from several parts. 3D printing enables manufacture of complex components which cannot be made using conventional methods, opening

Image: hawaii.

the way to unitisation. This is the ability to combine two or more simple parts, prior to assembly, into one large complex component.

Costs are reduced because both the part count and time required for assembly are reduced. The unitisation process is similar to modular building practices, where pre-fabricated rooms complete with internal fixtures and fittings are assembled on site.

Specialisation: 3D printing has found a niche in production of customised and speciality products such as bio-medical prostheses and intricate lost-wax casting moulds for jewellery designs.

Finding a 3D printer

Most metal 3D printers in Australia are only accessible through research institutions such as CSIRO and universities including RMIT and Monash.

CSIRO has initiated the Australian Additive Manufacturing Network to facilitate collaboration between research organisations and industry. The purpose of the network is to make effective use of 3D printers and assist Australian manufacturing companies to compete globally.

There is a growing list of service bureaus who can print sample pieces, enabling trial of the technology without the need to invest in an actual 3D printer.

3D printing is unlikely to fully replace conventional manufacturing technologies – but thanks to the savings in time, risk, and materials it offers, future factories are just as likely to include 3D printers as conventional machines.

This article was originally published at The Conversation. Read the original article.

12th August 2020 at 3:45 am

Development in 3D printing technology is supporting automotive industry in achieving unsurpassed aerodynamics. Whether it is the design of a vehicle, or making and testing prototypes, and final parts, this magnificent technology is refining manufacturing methods. We feel no inhibitions in proclaiming that 3D printing for automotive industry is all set to become a boon.

2nd July 2018 at 9:08 pm

FDM is a 3D printing technology developed for printing 3D objects in ABS thermoplastic materials. It uses high production grade thermal plastic materials for printing functional prototypes. FDM delivers objects that have greater details and precision in terms of dimensions and appearance. The printed objects are also mechanical, chemical, thermal, and electrical resistant. This technology is best suited for testing and fitting functional parts before mass production.