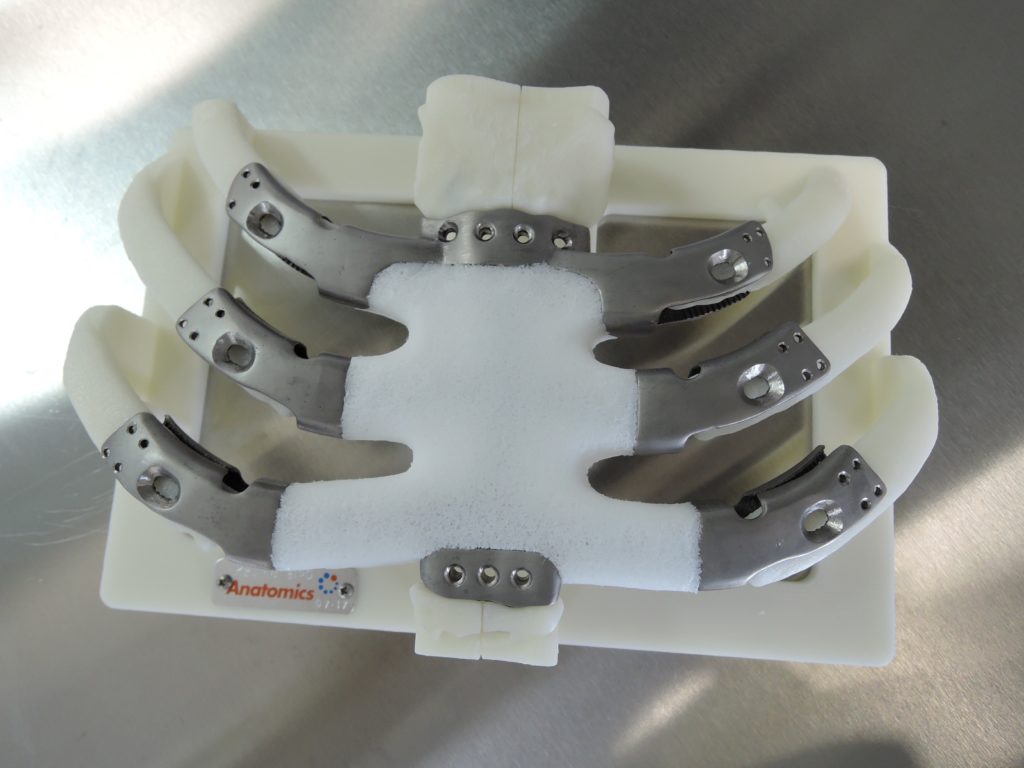

The 3D printed implant as shipped on its mount. Image: Anatomics

The 3D printed implant as shipped on its mount. Image: Anatomics

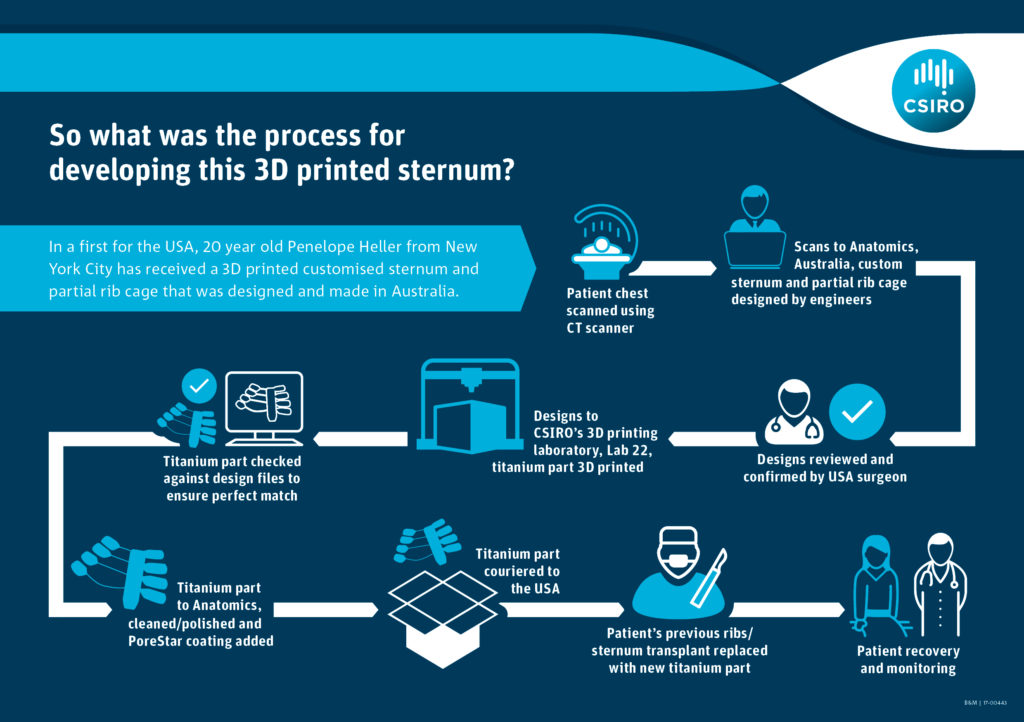

Start spreadin’ the news… NYC patient receives Aussie-made 3D printed sternum and rib cage implant.

When 17 year old Penelope Heller was diagnosed with chondrosarcoma (a rare bone cancer) in 2014, she was left with no choice but to have her cancer affected sternum removed. Her surgeon fashioned a replacement sternum and ribcage using off-the-shelf solutions and while the procedure effectively removed the cancer, ongoing pain and problems breathing made post-op life unpleasant for Penelope, so she searched for a better solution.

After reading an online article about a patient in Spain, she became aware of the possibility of 3D printed custom implants for sternal reconstruction. This patient underwent a similar operation to Penelope except they received a patient-specific titanium implant designed by Melbourne medical device company Anatomics and 3D printed at our Lab 22.

Penelope hoped this discovery could mark the start of a life-changing journey, so her family reached out to Anatomics to enquire about the possibility of accessing a 3D printed sternum and rib cage.

But they soon hit a road block. Anatomics did not yet have approval from the United States Food and Drug Administration (FDA) to market their patient-specific implant technology in the USA. Working with Anatomics and a surgeon who agreed to conduct the revision procedure, Penelope’s family sought FDA approval to access the implant under Expanded Access (Compassionate Use).

Success! On 2 August, 2017 the now 20 year old Penelope received her custom sternum and partial ribcage made from 3D printed titanium and combined with Anatomics’ ‘PoreStar’ technology, a unique porous polyethylene material providing “bone-like” architecture to facilitate tissue integration.

This is the first time a 3D printed titanium and polymer sternum implant procedure has been carried out in the United States, and only the second time in the world that a titanium part with PoreStar coating had been implanted, with a man in the UK undergoing a similar procedure in 2016.

3D-printed implant waiting to go in. Image: Anatomics

3D-printed implant waiting to go in. Image: Anatomics

It has now been over 60 days since her operation and Penelope, and her new sternum and ribcage, are doing very well.

Thanks to her persistence with the support of her family to find a better solution, Anatomics’ patient-specific implant technology, the 3D printing expertise of Lab 22, and the skill of her doctors, Penelope can now look forward to a pain-free and active life.

10th November 2017 at 1:25 pm

It’s good to know this kind of research and development has come about as I may just need it.. Will this remain an Australian product bring income back to Australia. So many good Aussie inventions go to overseas companies.

28th October 2017 at 2:09 pm

I am absolutely blown away, congrats to all involved. I would be interested to know the life span of this 3D replacement, the lifetime of the recipient?

9th November 2017 at 9:09 am

Hey Jeanette,

We referred your question to our Lab22 team, this was their reply:

“We have tested the corrosion of our Arcam 3D printed Ti6Al4V in simulated body fluid and it compares well with Ti6Al4V from casting, mill annealed product, and from other 3D printing processes. This is a standard alloy that has been in use for implants in other parts of the body. However, new Titanium alloys are being developed that may be even better from this long term point of view.”

Cheers,

Ellen

21st October 2017 at 6:15 pm

Brilliant – well done CSIRO

20th October 2017 at 7:49 pm

Awsome one for technology and the empathetic crew who made it all possible …..humanity to the rescue….

20th October 2017 at 11:59 am

Well done to all of those Men and Women at the CSIRO, whom were involved in bring this 3D Technology to fruition. With your research and help, medical science will proceed in leaps and bounds. ???