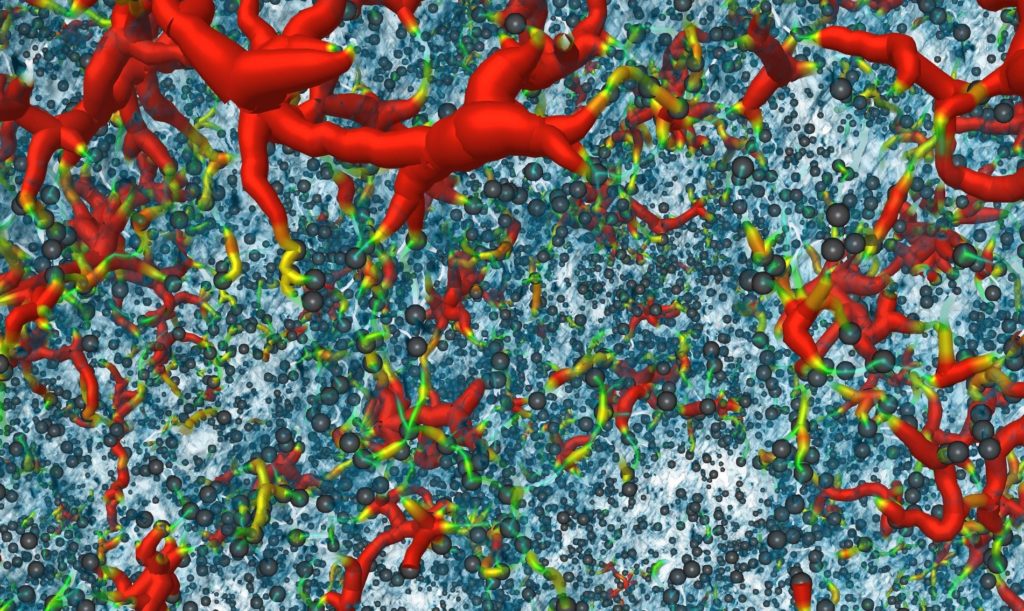

3D image of the mineral phase in iron ore

X-ray vision gave Superman the power to see through solid objects. Mere mortals have also discovered the power of x-rays using them widely in medical and scientific fields to visualise what would be unseen by the naked eye.

Our scientists have developed a new method using high-resolution x-rays to penetrate solid rock and reveal the minerals and elements hidden inside.

Called MicroCT, the process works in a similar way to medical CT scans but uses more powerful x-rays to penetrate complex and dense rock material.

Mineral analysis in 3D

Coupling this x-ray technique with 3D image analysis has allowed our scientist to create ‘digital rocks’ which show the distribution and characteristics of the elements within the rock sample, without destroying the sample.

Dr Belinda Godel and her team in Western Australia have been developing this technique for the mineral industry to use across the whole value chain, from exploration through to mineral processing.

“The MicroCT technology provides crucial data to use for imaging, but the strength in this method relies on its integration with other technologies to provide an accurate 3D characterisation,” Dr Godel says.

These technologies include optical microscopy, scanning electron microscopy, x-ray fluorescence mapping, laser-ablation inductively couple mass spectrometry (LA-ICP-MS) and electron back-scattered diffraction analysis; all available at our Advanced Characterisation Facility.

Traditionally, mineral characterisation is done in two dimensions. By visualising results in three dimensions a more complete picture is revealed, showing shape, size and what minerals are associating with others.

This information is important not just to show the presence and quantity of a target commodity but also how the ore was formed and how it can be processed.

With mineral deposits becoming harder to find and more complex to process, 3D digital images showing detailed rock characteristics will benefit the mining industry by helping improve productivity not just in mineral processing and metal production but also in the exploration for new mineral deposits.

For more information and examples of how this technique has been used in nickel and platinum group metals and iron ore see our recent article from resourceful magazine: Seeing on the inside.

Subscribe to resourceful

Our quarterly magazine brings you the latest in innovation, technology and research from the mineral resources sector.