What will the food industry look like in 2030?

What will the food industry look like in 2030? Can food be designed and structured to provide better nutrition? What foods will consumers want and how will technology change the way they eat?

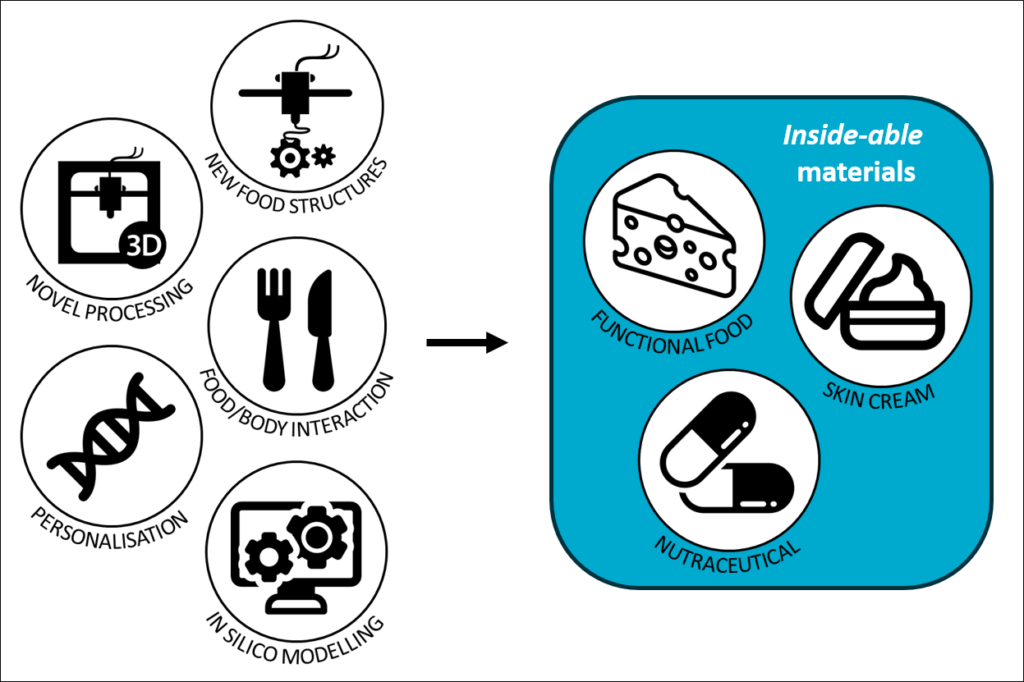

These are some of the challenging questions being answered by a multi-disciplinary group of scientists and engineers as part of a multi-year research platform aimed at developing smart and personalised inside-able materials. Inside-able materials enter the body, whether that be as a food or absorbed through the skin, to deliver superior health and performance outcomes.

Meeting the Needs of a Changing Consumer

Consumers are better informed and more aware than ever of what they eat. Their eating choices are based on nutritional information, sustainability of ingredient sources, and manufacturing methods. An increased number of consumers regularly monitor their activity and bio-response information through personal devices such as Fitbits to remain healthy. At the same time, people are becoming more and more time-poor and this is driving a trend towards seeking convenience in virtual shopping, delivery of goods/purchases and reduced food preparation time.

While food supplements are popular for some people wanting to improve their health, there is also a growing trend to go back to eating highly nutritious foods that may provide enhanced health benefits. Plus, consumers are increasingly interested in food that has been customised to meet their individual needs. Personalisation of food can be designed to meet functional and nutritional needs based on age, sex, health, activity level, food preferences or allergies and – in the not too distant future – genetic makeup.

Credit: Designed by Freepik from www.flaticon.com

What are the scientific challenges?

This exciting project looks at food customisation, and aims to design smart new inside-able materials and manufacturing technologies. They will incorporate information from sensors which monitor an individual’s health status and other information, including a person’s genetic makeup, phenotype and physiological conditions, to prepare a personalised smart food for optimum wellbeing.

The first step toward achieving this is understanding the relationship between food structure and how it behaves in-body throughout the digestive process. To do this, computational models will be developed that will help build our hypotheses and answer scientific questions.

For example how does the structure of a food affect the release and subsequent bioavailability of nutrients in the body, and how does this vary based on one’s genetic makeup and environmental factors?

The next stage of the research will focus on:

- identifying and developing food structures that can deliver nutrition to meet customised nutritional needs,

- developing the next generation of personalised and intelligent food technologies for the manufacture of smart, structured food materials, and

- integrating sensor technologies that measure food-body interactions with personal information (genetic, phenotype and lifestyle data) to inform food design.

The vision

While traditional food manufacturing is based on a one size fits all model, this research will move the food and nutraceutical industries towards products that are personalised to an individual.

We imagine a future where an intelligent ‘food generator’ will use personal information collected in real time, such as a consumers’ health status and what they are planning to do, combined with information such as their genetic makeup and age, to create a smart food matrix and nutrient load that is personalised to meet their requirements for that day. Ultimately, an intelligent ‘food generator’ would prepare personalised foods or inside-able material for each member of the family, on a daily basis.

For example – need more iron this morning after that busy weekend? What if our clever biosensing device could talk to our bench-top 3D printing food generator and create an iron-rich lunch designed especially for us?

Our project leader, Dr Amy Logan, explains that it is a difficult challenge to meet.

“To achieve something like this, we’re undertaking transformative science, and fusing innovative thinkers from across manufacturing, food formulation, health and wellbeing, consumer science, genomics, sensor technology, computational modelling and software disciplines”.

Personalised Fabrication of Smart Food Systems is a CSIRO-led collaboration working closely with scientists from national and international research institutes to deliver transformative science. This program builds on the combined knowledge of a multidisciplinary CSIRO team and renowned scientists from the Research Institute of Sweden, UMR STLO INRA-Agrocampus Ouest in France and RMIT University in Melbourne.

“We are keen to also work closely with industry, and encourage companies wanting to be part of this personalised food revolution to get in touch,” Dr Logan said.

Active Integrated Matter

The research platform is part of the Active Integrated Matter (AIM) Future Science Platform (FSP). The purpose of our FSPs is to take sci-fi dreams like this to reality, invest in science that underpins innovation and has the potential to reinvent and create new industries for Australia. AIM will lead ground-breaking advances at the interface of big data, advanced autonomous systems and materials science. Other AIM research initiatives include the creation of revolutionary robots, the development of new technology to monitor coral reefs, and eliminating food loss.

Dr Amy Logan, leads the Personalised Fabrication of Smart Food Systems project.

This work is part of CSIRO Agriculture and Food and the AIM Future Science Platform..

This is an edited version of an article that first appeared in Food Australia.