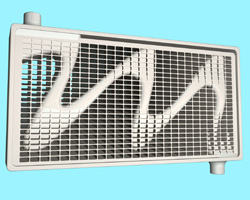

What do a radiator, a walking cane, a coat hanger and a doorknob have in common? Weirdly enough they can all be made from titanium and were just some of the candidates vying for top prize in last year’s Titanium Challenge.

The 2012 Challenge is now open – see the site HERE. There’s a 3D Printing Systems UP! printer and two trips to the USA up for grabs, so get to the website to find out what you need to do to be in the running.

The great thing about titanium is that it is strong and light, so it can be used for any number of things including car parts, tennis rackets and prosthetic hip joints. It is also more resistant to corrosion than many other metals, so it’s perfect for all of these applications.

At CSIRO, we love titanium and we want to spread that love to every engineering and design student in the land, through the Titanium Challenge 2012. We challenge you to come up with an exciting and innovative concept in one of the following categories:

- The Additive Manufacturing Challenge: design a novel component using additive manufacturing for a commercial market (aerospace, automotive, bio-medical or sporting goods).

- The Materials Challenge: use your knowledge of the performance–property–processing relationship to theorise about what should happen when powder is converted to product.

You have just nine days to get your entries in, so get those craniums working and show us what you’ve got.