By Tracey Nicholls

An Australian developed plastic cable coating material that transforms into fireproof ceramic in a blaze, has the potential to be a genuine lifesaver.

Leading cable manufacturer, Olex (a Nexans company), chose to partner with us to develop a new technology for making fire-resistant electrical cables.

Conventional polymers (a type of plastic), which cover electrical wiring, typically melt between 100°C and 200°C and disintegrate completely at about 300°C.

The challenge for us was to design a fire-resistant electrical cable that could keep electricity flowing in temperatures above 1,000°C.

The solution was a unique ‘ceramifiable’ polymer cable coating material, which combines the properties of a plastic with those of a fireproof ceramic.

When these cables are exposed to fire, the polymer melts. But instead of disintegrating, additives within the plastic react during combustion and solidify to form a ceramic layer over underlying electrical wires.

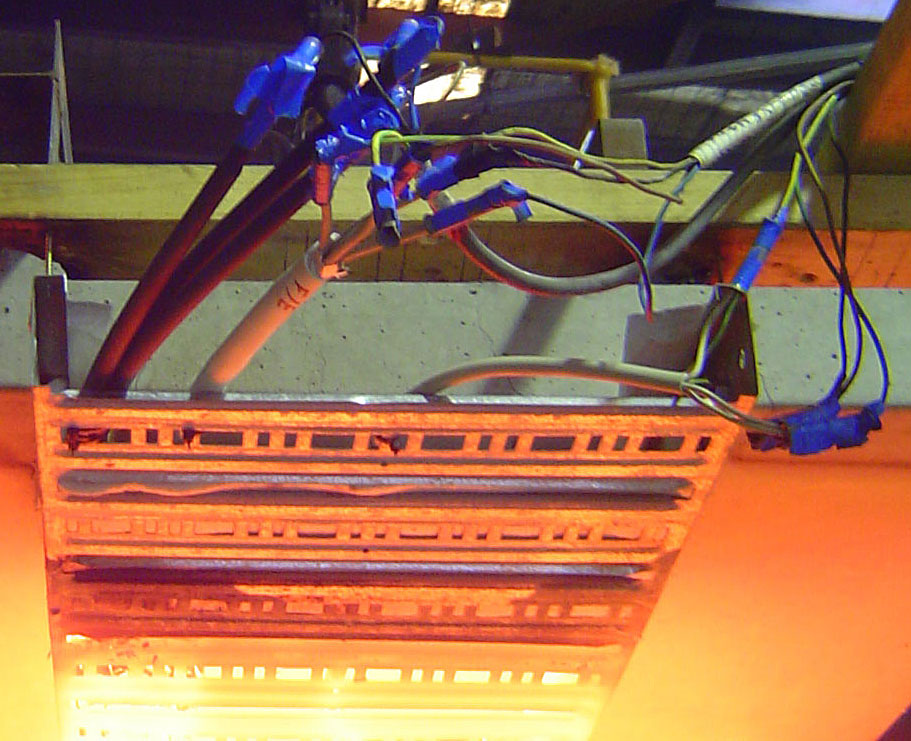

In the event of a fire, this unique technology will significantly improve safety. The cables’ ceramic shield maintains the integrity and continuity of circuits for essential services such as alarms, pumps and fans that are vital for safe evacuation and fire fighting.

Olex has supplied over 1,100 km of electrical cables to the Brisbane Airport Link Project in a contract worth $10 million to the company.

By partnering with Australian companies such as Olex, we are helping to transform existing industries and build future manufacturing opportunities, supporting job growth and economic benefit for Australia.

26th July 2013 at 5:55 pm

Fire resistant cable technology is a huge step towards advancement. Cable manufacturers in India are also researching further on this technology.