If you spend your days as a carpenter or lumberjack, you’ll be pretty used to the hassle of saw dust flying around.

But it turns out that airborne particles aren’t just a challenge for tradies – electronics manufacturers also have to deal with them, albeit on a microscopic scale.

When making electronics products, manufacturers have to cut through high-tech materials – like semiconductors and silicon wafers – meaning lots of tiny particles end up going to waste. As these materials are very expensive, this wastage turns out to be a much bigger problem than it is for your average tradie.

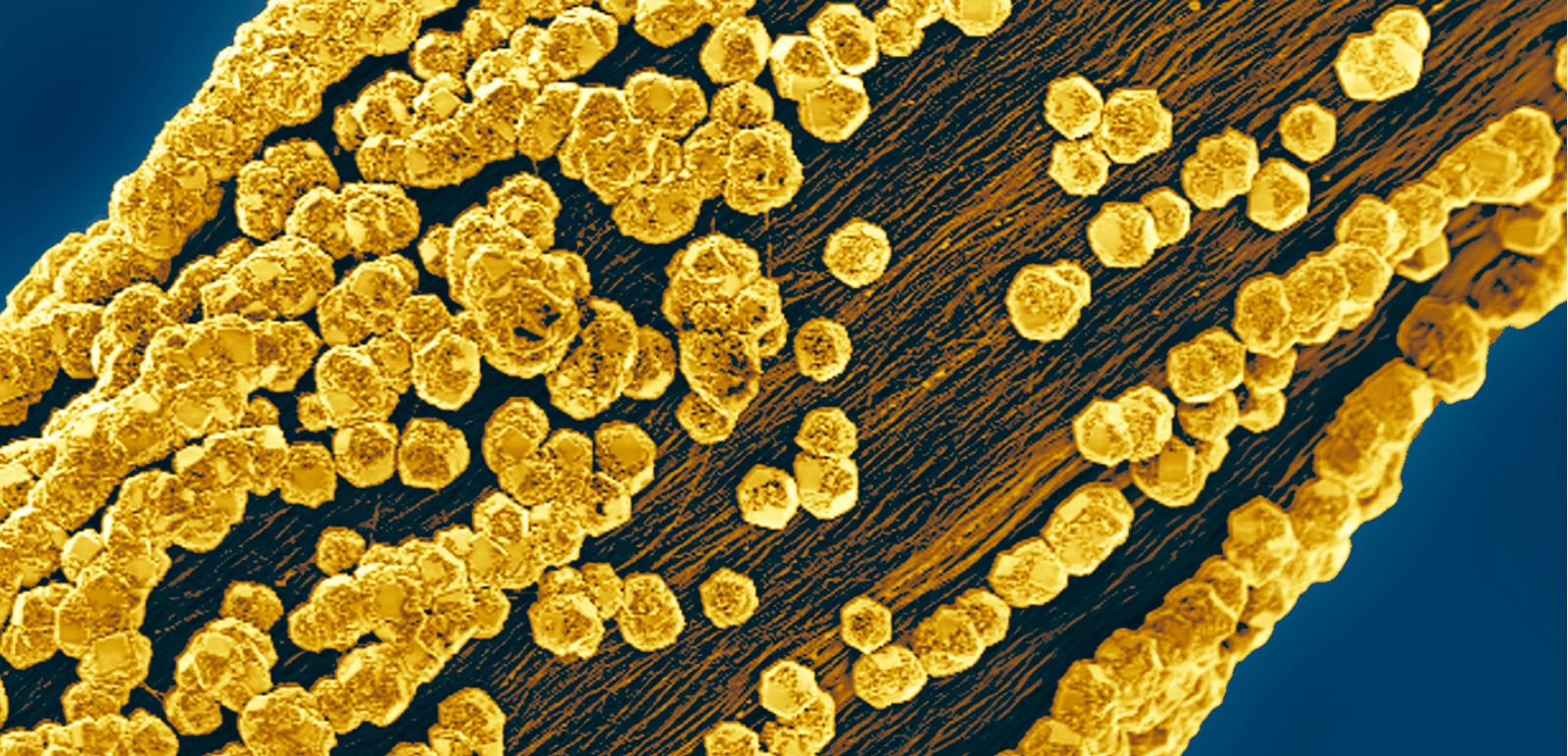

The new ultra-thin saw made of carbon nanotubes, and coated with diamonds

The new ultra-thin saws are made of carbon nanotubes and coated with diamonds. Credit: Fraunhofer.

To overcome the issue of high tech ‘saw dust’, we’ve been working with researchers from Germany’s Fraunhofer Institute to develop extremely precise itty bitty saw wires.

These miniature saws are made from ultra-thin threads made of carbon nanotubes coated with a layer of diamonds. This makes them much stronger than the steel wires that are currently used, meaning they can be manufactured much more finely.

Because they are so precise, they significantly minimise the amount of expensive material lost through flying particles – which will be a big win for electronics manufacturers.

Read more on the Fraunhofer website.