The porous structure of metal organic framework materials makes them perfect for storing and separating gases. Image: Flickr / Justus Thane

What do the Real Housewives of Melbourne and plastic have in common? You’ll be surprised to hear that it’s a Hollywood makeover.

We’ve developed a new material that prevents plastic from ageing, acting like a shot of collagen. And how will that freeze power costs? When applied to plastic lining (like those used in power generators) this material can clean up exhaust gases much more effectively than existing methods.

We’re not talking small figures here – consider that the current techniques used to separate out raw materials like gases, liquids and solids are extremely energy-intensive, making up a staggering 40 per cent of the world’s energy use each year. According to Dr Sam Lau, lead author, the new technique offers a solution that will make this separation a staggering 50 times faster.

This is how it works – at the moment power generators rely on plastic linings made up of tiny holes just one nanometre wide, a tiny fraction of a width of a human hair and for decades scientists have been trying to improve the process by using plastics with larger holes. But these larger openings tend to age very quickly and collapse within a matter of days.

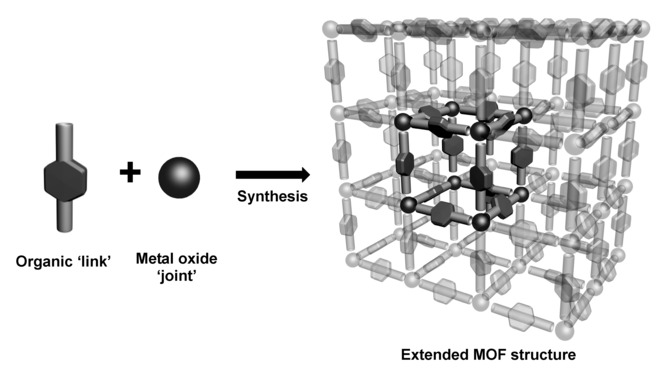

So scientists have been making use of incredibly compact materials knows as metal organic frameworks, or MOFs. These are solid materials with regular honeycomb-like structures – a little like the steel frame of a skyscraper – which can be prepared in the laboratory from organic molecules which form the links between metal atoms. MOFs have the surface area of a football field in just one gram. Combine this with their open sponge-like structures and they are ideal for separating mixtures of gases or for storing large volumes of a gas.

MOFs combine a cluster of metal ions and organic linkers to form a honeycomb-like structure. Image: Dr Christian Doonan, The University of Adelaide

This means the tiny holes in plastic lining can be made bigger, for longer.

“We found that the density of the MOFs acts like a shot of botox and actually freezes the larger holey structures in place for an entire year. This is a much more environmentally friendly approach and of course translates into huge cost and efficiency savings for the companies who take this up,” Dr Lau explained.

According to Dr Lau, not only does the technique have incredible potential for cleaning up exhaust gases from power plants, it could also be used to enhance the purity of natural gas streams, the separation of water from alcohols (a key process in biofuel synthesis) and for dye removal in the textile industry.

This means cost-saving all round which is a win for industry and, ultimately, your hip pocket.

***

Media contact: Liz Greenbank, Liz.Greenbank@csiro.au, +61 3 9545 8563 or +61 408 778 189