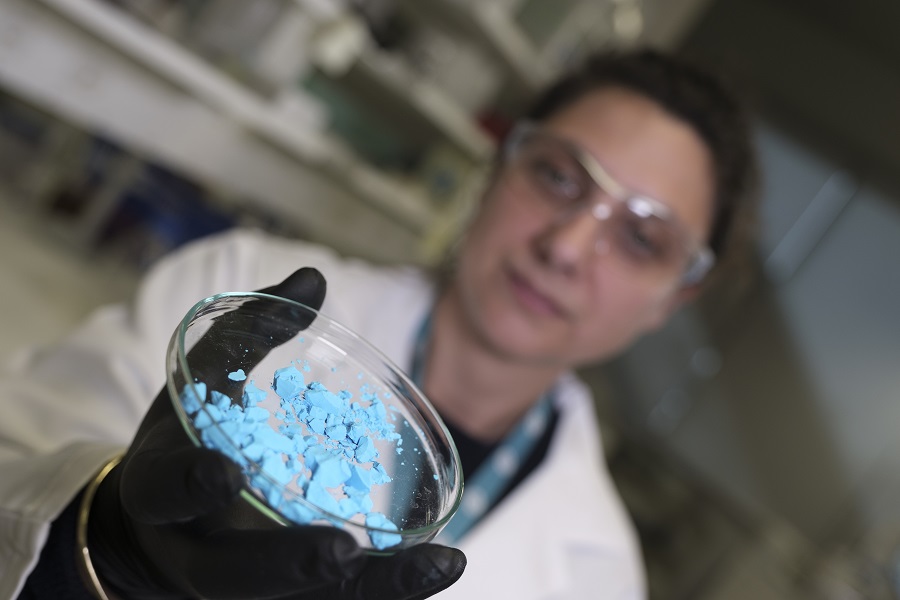

Advances in the manufacturing of the wonder material known as MOF is taking them from scientific novelty to industry’s next high tech hope.

Unless you’re a scientist, you’ve probably never heard of Metal Organic Frameworks, more commonly known as MOFs. That’s about to change though, as advances in the manufacturing of this wonder material take them from scientific novelty to industry’s next high tech hope.

MOFs are a crystalline material with the largest internal surface area of any material known. Just a gram of MOFs can have the same surface area as a football field. They’re also full of molecule sized holes, making them perfect for storing, separating, releasing or protecting just about anything.

Have a doctor or disaster response specialist that needs to transport fragile vaccines across rough terrain in Africa with no refrigeration? MOFs can do that.

Want to capture and store harmful gases created by an industrial process cheaply, efficiently and in a smaller space? MOFs can do that.

Need to filter industrial contaminants out of waste water before it can be released or safely stored? Yep, MOFs can do that too.

While scientists have long been aware of MOFs’ awesome potential the major roadblocks remained how to produce MOFs at a commercially relevant scale, purity and price.

Traditional lab setups often took days to produce just milligrams of MOFs using expensive chemicals which wouldn’t have been much use for industry. Some potential uses of MOFs, such as carbon capture for coal fired power stations or trapping natural gas so it can be used to fuel cars, require billions of tonnes of MOFs a year.

Now though, a paper published by our researchers together with the Catalan Institute of Nanoscience and Nanotechnology says innovative new techniques have turned MOFs into an industrial reality and commercial opportunity. These methods can produce vast amounts of higher quality MOFs safely, cheaply, efficiently and sustainably.

We use flow chemistry to create some of the world’s highest quality and most flexible MOFs quickly and at scale. We’ve even got our own burgeoning product development house for MOFs-based technologies, Mofworx.

Potential uses for MOFs include:

Drug delivery

Our researchers took one look at a sea urchin and thought “we can work with that”. Inspired by the hard shell sea urchins use to protect themselves, our team turned MOFs into tough, cage like structures that can protect and transport usually fragile substances without refrigeration. This technology could find its way into everything from more effective household cleaners to snake anti-venom bushwalkers can actually carry in their packs.

Gas storage

As MOFs have such an incredibly large surface area for their size, they can soak up large amounts of gas like a sponge. This ability to store, capture and release gases makes them a great solution for the car and energy industries. All while providing safety, environmental and commercial benefits.

Industrial processes

Practically every industrial process requires substances to be recovered, isolated or purified at some point. This can account for up to two thirds the operating cost! We’ve created ways to use MOFs and magnets together to act as a filter, capturing and removing pollutants such as heavy metals and hydrocarbons.

7th June 2017 at 7:10 am

Wonderful. And another great example of why funding for scientific research in this country should be not only sustained but increased. Australian research scientists are renowned and should be applauded in the same way we treat our sports heroes.

2nd June 2017 at 11:31 pm

Ummm… could they be used to suck carbon dioxide out of the atmosphere and sequester it?

7th June 2017 at 10:17 am

Hi Chris,

They can be used to sequester carbon dioxide. They can even be used to store carbon dioxide then release it when and where appropriate, eg. agricultural applications. You can find out more info here: https://www.mofworx.com/technology/

Cheers,

Ellen

CSIRO Social Media

2nd June 2017 at 11:21 pm

Useful for radioactive waste? Refrigerant gases ? Methane? Drying agent?

2nd June 2017 at 3:27 pm

impressive chemistry! Vast applications, how is the MOF “unloaded of it’s cargo?

2nd June 2017 at 3:41 pm

Hi Peter,

It’s a bit like squeezing out a sponge. We apply external conditions that make the cargo come out – this could be by using heat, vacuum, light, magnets, there’s quite a few options.

Check out this link for an example: https://www.csiro.au/en/Research/MF/Areas/Chemicals-and-fibres/Materials-for-industry-and-environment/Energy-production-and-capture/MOFs-solar-sponge

Cheers,

Eliza – social media team

5th June 2017 at 3:37 pm

Thanks Eliza

2nd June 2017 at 3:23 pm

Very good achievement, especially Mofworx, and the prospect of keeping some of the benefits of commercializing the technology here in Australia