Flubber is no longer a thing of fiction! Our scientists have developed their own. Image: ©Buena Vista Pictures/Courtesy Everett Collection

If you’re a 90s kid, chances are you’ve seen the classic 1997 Disney movie, Flubber. In case you missed it, Flubber sees a mad scientist, played by Robin Williams, inventing a wonder-material with extraordinary properties. The sentient gooey substance (called Flubber) is bouncy, stretchy, ductile, mouldable and able to change shape!

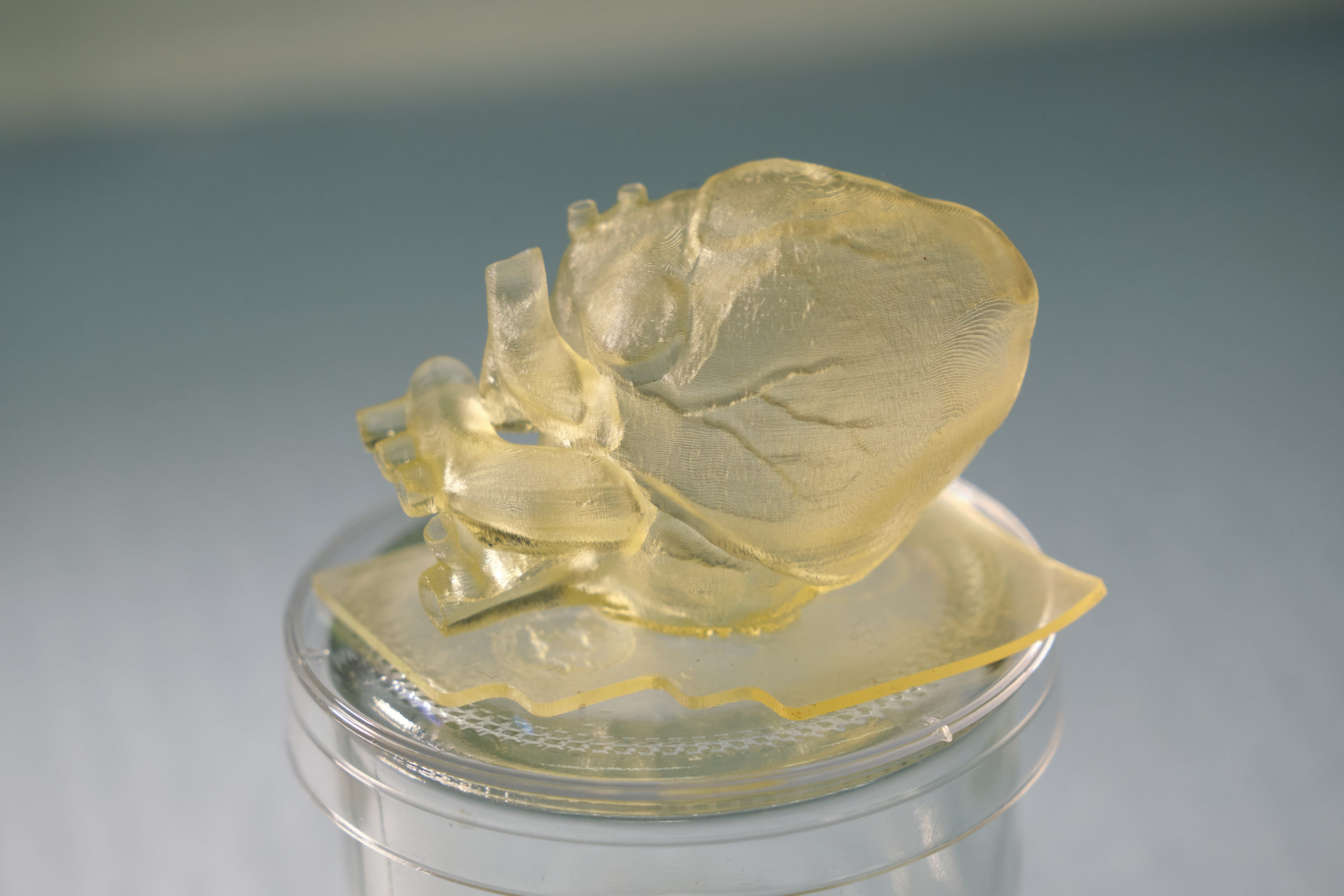

Deep in our biomedical polymer lab, our quirky, erm… brilliant scientists have invented their own “Flubber.” It’s a special silicone resin for 3D printing biomedical parts.

The tough, super soft silicone boasts some impressive qualities of its own. It has exceptional resilience, elasticity and compression. It offers tunable mechanical properties. And most importantly, and unlike any other silicone products currently on the market, you can use this special resin with off-the-shelf 3D printers.

You can “tune” the resin for use in both digital light processing (DLP) printing and potentially extrusion-based printing. That means you can optimise it to suit different applications and printers.

Who’s your Flubber now?

3D printing with silicone can be tricky, with current resins offering slow print times and relatively low resolution. Also, current resins can only be used on specially customised printers, and that can be expensive.

Our team has found a way to solve this dilemma by developing an exceptional silicone resin for common, off-the-shelf 3D printers, without the need for modification.

Scaling up the resin is simple because it is easy and safe to make. Its adjustable viscosities, which our scientists can “tune” depending on the application, make it easily transferrable to other 3D printing techniques.

3D printed silicone has great potential. And researchers expect the Global Silicone Market to reach $91.4 Billion by 2026.

Sticky solutions

But wait! There’s more! … and this is a bit random. Our resin has also demonstrated additional superglue properties, making it an excellent adhesive for metal and glass. This means it also has completely separate applications as a construction adhesive!

We’ve patented this novel silicone resin, and we think it will pave the way for a new era of manufacturing in silicone printing.

![]()

We’re seeking industrial partners to help us commercialise the product. So if you’re interested, get in touch.

We’re supporting work led by the Department of Industry, Science, Energy and Resources (DISER) to implement the Modern Manufacturing strategy, which is a whole-of-government strategy. It’s aimed at helping Australian manufacturing scale-up and become more competitive and resilient — creating jobs for now and future generations.

8th September 2022 at 7:51 pm

3D-printed silicone can become a scientific breakthrough in various fields. Hopefully, the project has already found investors

19th August 2021 at 10:49 pm

Please keep me posted on when it’s commercially available and from where

24th July 2021 at 2:22 pm

Sorry, the Nutty Professor, Fred McMurray invented flubber in the 1960s!

19th August 2021 at 10:47 pm

Absolutely, and it was the better movie too.

23rd July 2021 at 4:45 pm

Let’s hope CSIRO sell it properly and get a good deal, not like they did virtually giving away their original WiFi technology patents.

24th July 2021 at 6:08 pm

Not everything needs to be commodified and those innovations that best benefit all of mankind should be made available freely.

22nd July 2021 at 6:23 pm

Sounds amazing. No mention of durability but if that’s not an issue then endless applications.