In a modern take on the classic Chitty Chitty Bang Bang, our team at Lab 22 have 3D printed a replica engine block to give a 1914 race car new wings.

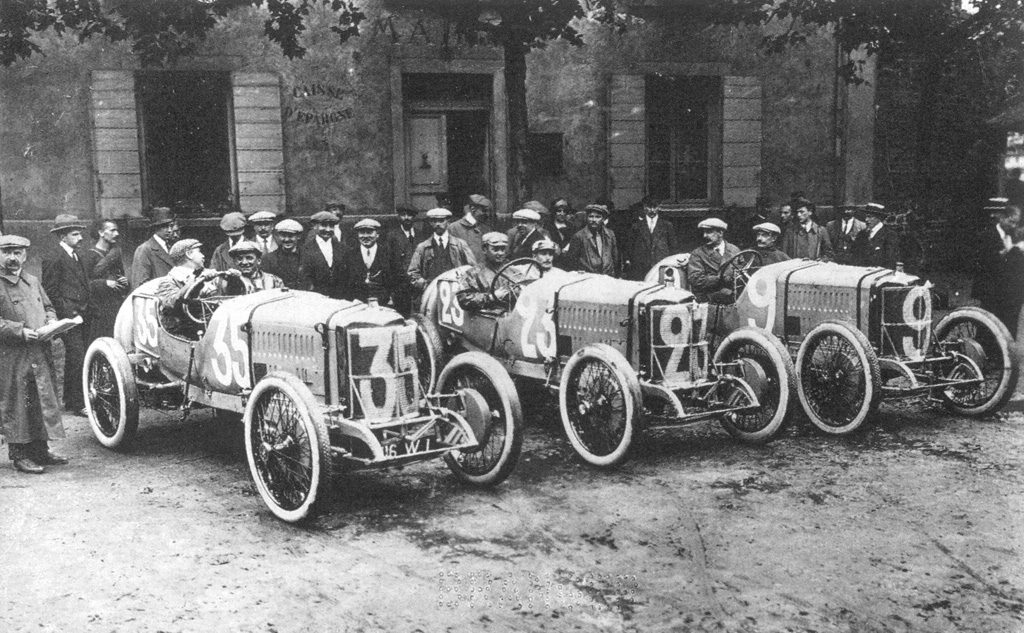

Vehicles lined up for the 1914 Grand prix

The Delage Type S placed 3rd in the 1914 Grand Prix.

We all love the classic ’60s film Chitty Chitty Bang Bang right? A wonderful musical adventure (and maybe horror too, what was with that weird guy that stole the children?!) film in which we watch Dick Van Dyke put on numerous musical numbers to save and restore an old racing car for his two precocious children. You may not know it, but our scientists in Lab 22 are bit Dick Van Dyke-esque (the car restoration, not the singing and dancing – though they’re probably good at that too!).

Our team was approached by an Australian car enthusiast who was painstakingly restoring a 1914 Delage Type S (a French race car for all the non-enthusiasts out there) – that also happens to be the only one left in the world. The Delage was a revolutionary racing car for its time, boasting the latest innovations in automotive technology. In fact, this very automobile placed 3rd in the 1914 Grand Prix. Sadly after 103 years the engine block (which is the body of an engine, a very important part!) was looking a little worse for wear – so our team were asked to help them make a new one.

But just how do you clone a 1914 engine block without detailed plans or traditional manufacturing methods? With sand of course!

Sand them over here

Hear us out – we know that sand is coarse and rough and irritating and it gets everywhere but when we put our heads together with our project partners it was the obvious choice! Before we could start building our engine we had to figure out exactly what it should look like.

A near perfect replica of the 1914 Delage engine.

A near perfect replica of the 1914 Delage engine block. Image- Phil Guilfoyle, Vintage Restoration Management Pty Ltd.

To do this, advanced 3D scanning and printing company, WYSIWYG 3D, made a digital copy of the existing engine by scanning the original block to accurately capture its every detail. This helped us make a virtual block that could be checked, simulated and modified as needed.

We then rolled out the Voxeljet VX1000 – and if you’re thinking that name sounds really cool and it must be an amazing piece of equipment, then yeah, you’re right! The Voxeljet VX1000 is our 3D sand printer housed at Lab 22, and its Australia’s only sand printer. So we put the virtual block information into the Voxeljet to create a 3D printed sand mold, which later had cast iron poured into it by Keech Australia to make a casting (you can even check out the process in action here).

Restored 1914 Delage race car

Completely restored to its former glory – the sole surviving 1914 GP Delage. Image – Phil Guilfoyle, Vintage Restoration Management Pty Ltd.

And voila! A brand new 1914 engine block!

Of course, the Delgae can’t hover on water or fly like our good mate Chitty, but we still think our team at Lab 22 are doing some pretty magical work.

31st March 2017 at 4:32 am

I must say well done and congratulate the team for such a wonderful job. We too are a 3D printing service company in Canada and i can truly relate what such great achievements mean to the team. Keep the good work up!

28th March 2017 at 3:27 pm

The method of sand casting to produce a new block would have been chosen specifically to create a reproduction with all the characteristics of the original. Its neither a new or irritating method for casting. Such a pity that the CSIRO needs to dumb pun itself down as clickbait.

5th April 2017 at 5:52 pm

To me it is a great story. To you? I don’t know, seeing I do not mix with great and important figures. I don’t know how their superior minds work. In the meantime, I salute you, o Great One!

5th April 2017 at 7:55 pm

Well I’m glad about the click bait as I wouldn’t have read about the 3D printed sand casting. I do 3D printing for a living and I am glad that the CSIRO can do this method of sand casting . I have a small foundry at home and am very interested in finding out more about this. Great job guys.