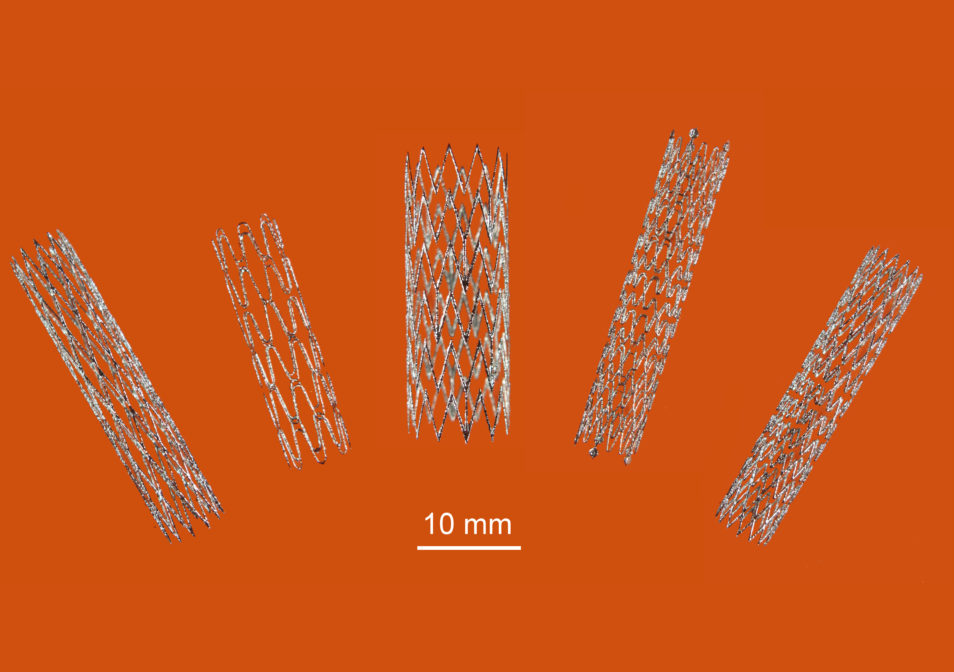

World first 3D printed nitinol stents.

There are lots of things you can achieve through 3D printing. But you may not have thought of a life-saving 3D-printed artery stent.

Traditional manufacturing is good at making lots of copies of the same thing. But with 3D printing we can make things to measure. This is particularly useful when it comes to designing parts for the human body.

Off the shelf

Ten per cent of the world lives with Peripheral Arterial Disease or PAD. The cause is a build-up of plaque in the arterial system. It affects circulation to the body’s extremities, usually the legs.

There are few treatments better suited for PAD than the self-expanding artery stent. These are little tubes doctors can insert into arteries to aid blood flow. Off-the-shelf stents are made in a range of different shapes and sizes. But everybody’s circulatory system is diverse and blockages can occur in various places.

For surgeons, this means managing a large stock of different size stents at the hospital. Stents are expensive and have a shelf life or expiry date. So unfortunately, surgeons have to discard unused stents once they reach their expiration date.

A surgeon who treats patients with vascular disorders saw a need for change. With manufacturing improvements in recent years, he wondered if it might be possible to create a custom-made self-expanding stent using 3D printing.

3D printing technology

3D printing has become the go-to technology for made-to-order, small-scale manufacturing. However, there were challenges making stents with 3D printing. Particularly those made from nitinol, the alloy of choice for such devices.

It’s not easy for a machine to make a metal mesh cylinder. It is less than one centimetre in diameter, with features of 0.1 – 0.2 millimetres. And it needs to be safe enough to implant in the human body. Our Lab22 Centre for Metallic Additive Manufacturing had the answer for the bespoke stent: Selective Laser Melting.

The tiny mesh shape of a nitinol artery stent can melt into place on a bed of fine nitinol powder. It is built up layer by layer with high geometric accuracy using this form of 3D printing. Nitinol is already in use as an alloy for traditionally made stents. This new form of manufacturing allows for made-to-measure customisation for the patient. The technology also lends itself to mass manufacturing.

Nitinol has its challenges in 3D printing

Nitinol’s properties change depending on the level of heat it’s exposed to. It can become super-elastic, stay rigid or bend and flex whilst retaining its original shape. Nitinol can be made into a stent small enough to insert into a patient. Then body temperature makes it spring back into shape. These characteristics make nitinol the perfect alloy for stents. However, it is a challenge when 3D printing because it is so sensitive to temperature changes.

With every beat of your heart

The team were able to strike a balance in the nickel-titanium makeup of nitinol, so it retains its flexibility as a stent. The result is a proof-of-concept 3D-printed stent, promising the perfect fit for patients. It will also help hospitals cut down on perishable inventory.

This isn’t the first time our team at Lab22 has turned their hand to medical 3D printing. They helped develop the world’s first 3D-printed titanium heel. Not to mention the 3D-printed sternum and partial rib cage.

A new company has come off the back of our 3D-printed nitinol stents, Flex Memory Ventures. The goal is to commercialise the technology. This will make it possible for hospitals to manufacture their own stents on demand someday.

29th June 2020 at 2:28 pm

Excellent innovation, although having myself been a recipient of 2 stents that failed after only 2 years I would say bypass grafts are a longer lived means to address PAD

10th June 2020 at 8:17 pm

Could be a useful stopgap technology while we wait for nanoassemblers to become a reality. But seriously, nice work.

10th June 2020 at 4:23 pm

Quite excellent and a credit to all concerned. Thank you.